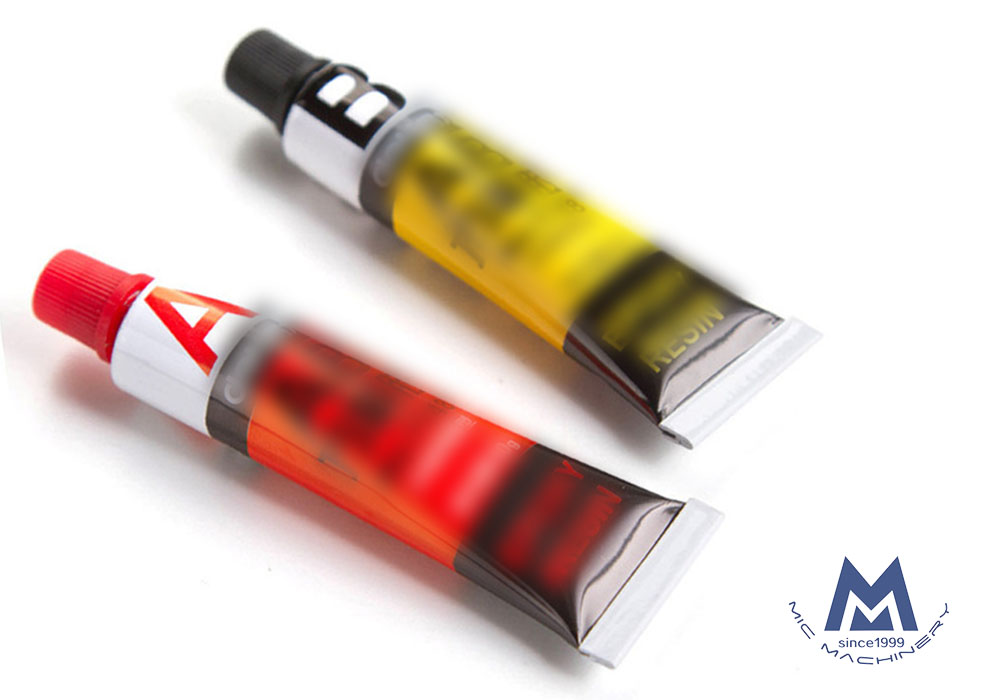

This tube filling sealing machine is suitable for:

super glue, glue 502, cyanoacrylate adhesive AB glue, gel glue, paint, space food, hair color dying cream, cosmetics, medical products and other similar products.

This machine function is:

1. Automatic tube clamping and sealing

2. Automatic tube loading tunnel

3. Automatic tube logo marking

4. Automatic material feeding system (optional)

5. No tubes no fill and date printing

6. Can equipped nitrogen filling system, and tube lifting filling system.

7. As different material, we can also make sure no air inside products while filling.

8. Automatic counting and tube outlet

9. Can be customized for different tube and liquid

10. Can be equipped different tanks and mixers

This machine filling system is made for specially for aluminum tubes, easy clean and changes, it is a practical machine for aluminum and metal tube packaging, 24 hours runs none stops, hardly have machine break down once well adjusted.

Machine filling accuracy max is at 0.1-0.5g, from 3ml-250ml with different filling piston pump.

This machine is mechanical transmission, logo marking has only 0.3 degree error, normally in china market is 1 degree, you can choose how to fold your tubes by show your ideal pictures.

The sealing divider speed reaches 60 piece per min, compare to other usually company, we can really do 60 piece per min, not just design theory, machine running without noise.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

About the machine use problem, after the sales,

we will take video for:

1. how to connect the power

2. how to operate the machine

3. how to maintain the machine and how often to do it

4. how to adjust machine to different bottle or material.

Thank you for the reading this article,

you can also check video for:

|

Weight |

850Kg |

|

Dimension |

1950*800*1850mm |

|

Power |

220V/50Hz |

|

Motor |

2.2Kw |

|

Filling Quantity |

3-30ml/30-75ml/75-150ml |

|

Capacity |

30-75 tubes/min |

|

Suitable Filling Material |

Aluminum tube |

|

Maximum Tube Dia. |

80mm |

|

Date Printed |

1-2 rows(numbers & letters) |

|

Additional Function |

Air Blow after filling |

|

Parts |

Brand |

|

Framework |

SUS 304 Stainless steel |

|

Touch Screen |

Simems |

|

Main Motor |

Taiwan, Mingbang |

|

PLC |

Siemems |

|

Stepping Motor |

Japan EAST |

|

Stepping Drive |

Japan EAST |

|

Color Mark Sensor |

Germany Sick |

|

Approch Switch |

Omron |

|

Media Relay |

Omron |

|

Heater Gun |

Switzerland Leister |

|

Magnetic Vavle |

Taiwan AIRTAC |

|

Protractor |

China, Shangdong |

|

Stirring Motor |

XiangGang EAST |

|

Pneumatic Elements |

Taiwan AIRTAC |

|

Pump for Filling |

Own produce (MIC) |

|

Hopper (50L) |

SUS316 |

|

Bearings |

Japan NSK |

|

Buttoms |

Schneider |