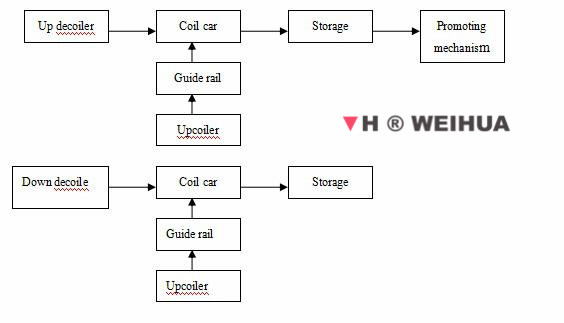

Our production line including up decoiler and down decoiler, each decoiler has coil car, hydraulic station, decoiler body, our company has two type decoilers ,one has assist support device, the other do not has the assist support device. 1)The decoiler has two type. One type with assist support, the other without.

2)Two control type, one is using light switch ,the other is

3)Support design: The structure is more reliable than the hinged type frame, and 5Ton hydraulic can not working stable for a long time without this support design.

4)Coil drum: four pcs nest, provide 508mm and 610mm two size, when the coil inner diameters want to change into 610, can assembling the four arc plate and insure the hydraulic expand lock to insure the expand force.

5)Assistant supporter:during the production of PU continuous line, it needs to reduce the connection of steel coils, so the loading requirement of uncoiler is high. Meanwhile, in order to avoid the drooping of main shaft and off tracking of steel coil, uncoiler adopts assistant supporter to guarantee the loading of 10T coil without the deformation of main shaft. The assistant supporter of uncoiler adopts quick hinge type, operation is very convenient, so that the production line will not stop during the connection of steel coils’ends.

6)The assistant supporter of uncoiler adopts quick hinge type, operation is very convenient, so that the production line will not stop during the connection of steel coils’ends.

7)Above mentioned measures can guarantee the changing time of steel coil within 45 seconds;

8)Drive system:positive and negative rotation carry out the uncoiling and recoiling, the main shaft of uncoiler is driven by motor and reduction box to carry out the active uncoiling,and also used for recycling of unfinished production steel panel. When active uncoiling,the speed can be synchronous with production line, there is ultrasonic wave detecting for tracking the speed of main line, whole process is frequency conversion controlled;

9)Uncoiler has material pressing unit, which is fixed above with the angle 30-40°, avoid collision with up machine machine frame;

10)Lifting table:oil hydraulic motor drives lifting table move along the guide rail, the guide rail is lengthened to avoid collision of steel coil and up machine machine frame.

1)Every uncoiler includes coiling block, machine base and drive system, it adopts hydraulic cantalever expanding and has manual centering device;

2)Type of coil:painted steel coil, aluminium coil;

3)Thickness of steel sheet:0.4-0.8 mm;

4)Inner diameter of steel coil:φ508mm、φ610mm;

5)Outer diameter of steel coil:φ1800mm;

6)Weight capacity of steel coil:10T;

7)Uncoiler has assistant supporter:bearing, hinge, lock, leadscrew adjust supporter;

8)Width of steel coil:Max 1250mm;

9)With material pressing device:it is fixed at 30-40°above,which can avoid the loosing of steel coil during uncoiling; 10)Lifting table(1 pc):hydraulic motor drives lifting table move along the guide rail;

11)A pair of rails;

12)One set of hydraulic system;

13)One set of electrical control system;

14)Arc board,4 pcs;

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material