Cut To Length Line

3

Share

TECHNICAL PARAMETER

COMPONENTS

COMPONENTS

a. Thickness of material:0.5mm-3.0mm

b. Width of material:1500mm

c. Material for processing:cold rolled coil, hot rolled coil, painted coils, galvanized coils

d. Outer diameter of steel coil:≤Ø1800mm

e. Inner diameter of steel coil:Ø508mm, Ø610mm, Ø762mm

f. Weight of steel coil:≤15T

g. Tolerance of cutting length:±0.5mm (take panel of 1.5mm thickness and 2000mm length for measurement)

h. Tolerance of diagonal:±1.0mm (take panel of 2m length for measurement)

i. Cutting speed:21 pcs / min(take panel of 2m length for measurement)

j. Leveling speed:0- 60m/min

k. Quantity of working roller:19 rollers

l. Diameter of working roller:¢60mm

m. Material of working roller:90Cr2MoV

n. Hardness of working roller:HRC58°-60°

o. Quantity of middle roller:21 rollers

p. Material of middle roller: 9CrSi

q. Hardness of middle roller:HRC50°- 52°

r. Quantity of supporting roller:138 rollers (6 rows)

s. Weight capacity of stacking lifting table:5000kg

t. Stacking length range:500-4000mm(side discharge)

u. Max. stacking height:400mm

v. Floor area:about 24000 × 7000mm (L × W)

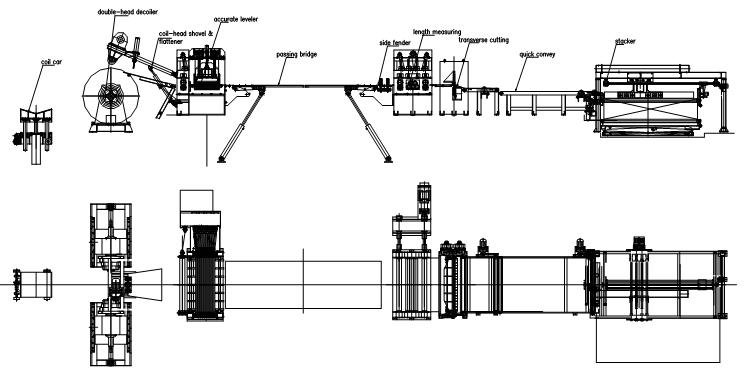

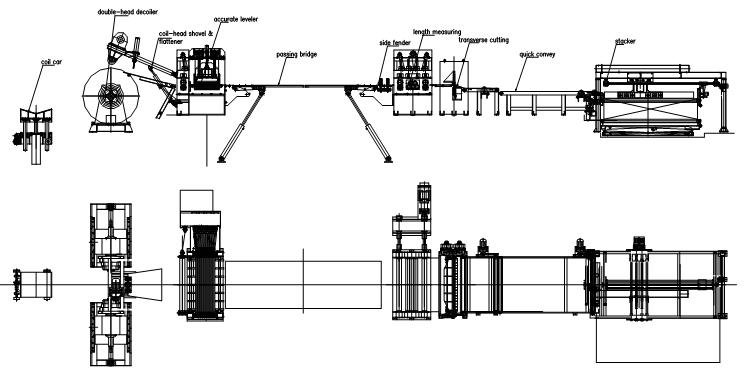

FLOW CHART

b. Width of material:1500mm

c. Material for processing:cold rolled coil, hot rolled coil, painted coils, galvanized coils

d. Outer diameter of steel coil:≤Ø1800mm

e. Inner diameter of steel coil:Ø508mm, Ø610mm, Ø762mm

f. Weight of steel coil:≤15T

g. Tolerance of cutting length:±0.5mm (take panel of 1.5mm thickness and 2000mm length for measurement)

h. Tolerance of diagonal:±1.0mm (take panel of 2m length for measurement)

i. Cutting speed:21 pcs / min(take panel of 2m length for measurement)

j. Leveling speed:0- 60m/min

k. Quantity of working roller:19 rollers

l. Diameter of working roller:¢60mm

m. Material of working roller:90Cr2MoV

n. Hardness of working roller:HRC58°-60°

o. Quantity of middle roller:21 rollers

p. Material of middle roller: 9CrSi

q. Hardness of middle roller:HRC50°- 52°

r. Quantity of supporting roller:138 rollers (6 rows)

s. Weight capacity of stacking lifting table:5000kg

t. Stacking length range:500-4000mm(side discharge)

u. Max. stacking height:400mm

v. Floor area:about 24000 × 7000mm (L × W)

1.Hydraulic coil car

2.Double-head type decoiler

3.Coil head shoveling & leading unit

4.Feeding device

5.19-roller accurate leveler

6.Passing bridge and storing pit

7.Guiding device

8.Servo length measuring unit

9.Transverse cutting device

10.Conveying table

11.Automatic stacker

12.Discharge car

13.Hydraulic system

14.Electrical control system

15.Other components

Products

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material

TOP