Principle

The milling basket, containing thegrinding bead is lowered into the millbase, the fast circulation of the millbase within the milling basket is generated by the dissolver disc and integrated pump wheel, a very narrow particle size distribution can be achieved very quickly.

Characteristics:

● Suita for producing small batch product and middle test. Dispersing and grinding are finished in one machine and one container, no need extra pumps, piping, valves etc .

● Easy cleaning, no residues, convenient product replacement.

● Little grinding media required.Excellent grinding efficience and effect.

● Double-walled container for cooling and heating.

● Modular design of parts make it much more convenient to disassemble, maintain and overhaul, almost no need of professional maintainer.

Materials Viscosity: ≤ 5000 cps

Production Capacity: 50-3000L

Application Industry: Suitable for dispersing, grinding materials in industries such as biology.pharmacy, cosmetic, food, paint, ink, color paste, dyestuff, fertilizer etc.

Applicable Materials: Materials shall be with viscosity less than 5000cps, with comparatively high requirements of final grinding result or with many varieties such as emulsion paint, industrial paint, color paste, water-borne ink, fertilizer suspension, etc

Product Advantages

● High grinding efficiency and excellent grinding result

Driven by the strong kinetic energy, the zirconium pins drive the grinding medium inside the basket to carry out irregular movement. The mediums crush, friction with each other to grind the powder into smaller particle size within a short period. For general materials, it can be down to approx. 5um, some even can be down to submicron or even nano level.

● Convenient and safe operation

Adopt hydraulic tank as liting actuator. Control the hydraulic up, stop, down through the oil pump, easy operation and stable.With different clamping types to fix the tanks properly to prevent from accident due to the tank displacement during operation.Little temperature increase, stable finished product.

The tank working with the machine is with cooling jacket. Excellent cooling result can be achieved by inputting cooling water into the jacket when the machine is running . Normally thetemperature increase will be less than 10. Basket part with jacket can be customized.Customized options

● The machine can be Exproof type.

● Grinding chamber can be made of Zirconium.

● The machine can be vacuum type.

● The materials for the machine can be SS316L

The rotating motor drives the pins and dispersing disc to rotate at high speed, which makes the upper part of dispersing disc and inner grinding chamber become vacuum. The slurry is inhaled into grinding chamber. The grinding medium driven by the driving pin inside the chamber produces force in all directions,which put materialsunder the action of constant collision and friction to smaller the particle size andnarrow the particle size range. The vortex flow generated by high speed rotation dispersing disc absorbs materials out from the basket (grinding

chamber), and the milled materials are absorbed again, excellent dispersing and grind result will be achieved.

Lift the hydraulic piston by running the hydraulic pump to have the driving mechanism and grinding chamber lift up and down.

|

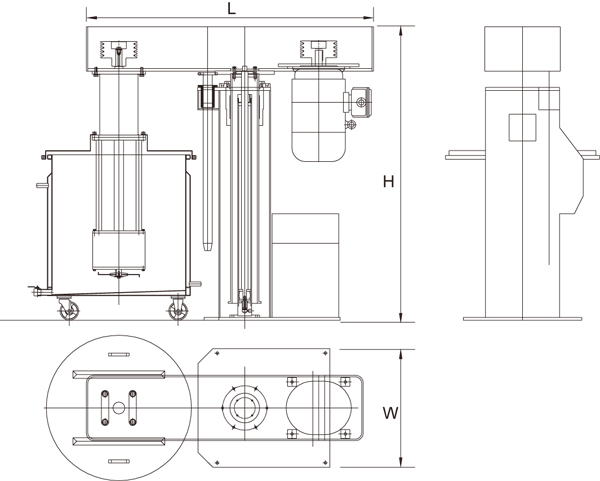

Type/parameter |

Voltage |

Power |

Speed |

Handling capacity |

Basket capacity |

Lifting height |

Milling medium |

Overall size |

||

|

L |

W |

H |

||||||||

|

FTM-50 |

~380 |

2.2 |

0~1500 |

10~50 |

1 |

400 |

1.8~2.0 |

2400 |

2400 |

2400 |

|

FTM-100 |

~380 |

4 |

0~1500 |

30~100 |

2 |

500 |

1.8~2.0 |

2400 |

2400 |

2400 |

|

FTM-200 |

~380 |

7.5 |

0~1500 |

50~200 |

4 |

600 |

1.8~2.0 |

2400 |

2400 |

2400 |

|

FTM-250 |

~380 |

11 |

0~1500 |

80~250 |

6 |

700 |

1.8~2.0 |

2400 |

2400 |

2400 |

|

FTM-350 |

~380 |

15 |

0~1500 |

150~350 |

10 |

800 |

2.0~2.4 |

2400 |

2400 |

2400 |

|

FTM-500 |

~380 |

18.5 |

0~1500 |

200~500 |

16 |

900 |

2.0~2.4 |

2400 |

2400 |

2400 |

|

FTM-1000 |

~380 |

22 |

0~1500 |

400~800 |

20 |

1000 |

2.0~2.4 |

2400 |

2400 |

2400 |

|

FTM-1500 |

~380 |

30 |

0~1500 |

800~1200 |

30 |

1100 |

2.0~2.4 |

2400 |

2400 |

2400 |

|

FTM-2000 |

~380 |

45 |

0~1000 |

1000~2000 |

70 |

1300 |

2.0~2.4 |

2400 |

2400 |

2400 |

|

FTM-3000 |

~380 |

55 |

0~1000 |

1000~3000 |

100 |

1500 |

2.0~2.4 |

2400 |

2400 |

2400 |

|

FTM-3500 |

~380 |

75 |

0~1000 |

1000~3500 |

180 |

1600 |

2.0~2.4 |

2400 |

2400 |

2400 |