Characteristics

●This machine has stable structure ,ingenious design design and convenient operation.

●Cleaning、changing colour and replacing mill bead can be much easier.

●Non –vestigital design, it can solve the problem of material discharging better after milling.

●Hard alloy sticks, with proper redistribution, high-efficiency milling result can be obtained.

●Double cooling of inner rotor and outer jacket ensures effect of material cooling.

●Better lining of wear-resistant alloy, without pollution to materials.

●With less abrasion of milling media and cost.

Product Advantages

Novel structure, high stability

Strengthened frame with reasonable structure, steady operation and easy maintenance. Besides, nicer appearance with full of modern sense. The main parts an out-sourced parts areinternationall renowned brands with higher stability and longer service life.Easy to clean, strong durability

Unique tri-pole mechanism design makes it easy to open for cleaning and replacing grinding chambers. The grinding chamber, made of high wear-resistance alloy steel, is treated specially torealize higher wear resistance and longer service life. In addition, Burgmann Dual-end Mechanical Seal with self-lubricating system contributes directly to higher reliability and durability.Safe monitor, stable product

The machine is with triple cooling: internal, external, and end face, which ensures the grinding heat exchanged out in time. The water temperature, material temperature, material pressure,water pressure, air pressure and other real-time monitoring and protection system ensure proper operation of the machine.Full specification, can be customized

Specifications ranges from 2L to 50L, which can be customized to be Exproof type.

Working Principle

The delivery pump circulates the materials in the tank and the materials in the grinding chamber. The main shaft in the grinding chamber is equipped with many pins with high anti-abrasiveness and hardness. The pins drive the grinding medium inside the grinding chamber to do irregular movements in all direction to put the materials undert the action of constant collision and friction. At same time, the materíals are separated from the grinding medium by dynamic and static ring and keep circulating from the tank to the grinding chamber to obtain smaller particle size, narrower particle size range.

|

Type/Parameter |

Motor power |

Barrel capacity |

Pump flux |

Cooling water |

Production capacity |

Milling medium |

Overall size |

||

|

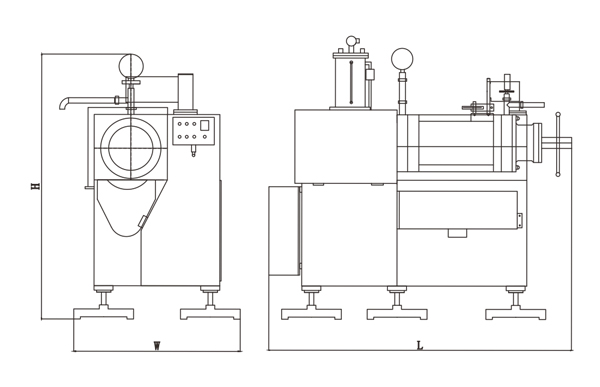

L |

W |

H |

|||||||

|

FTBS-2 |

3 |

2 |

2~12 |

0.5~1 |

20~100 |

0.8~2.0 |

1300 |

1100 |

1000 |

|

FTBS-20 |

22 |

20 |

2~12 |

1.5~2 |

100~500 |

0.8~2.0 |

2100 |

1200 |

2000 |

|

FTBS-30 |

30 |

30 |

2~12 |

1.5~2 |

100~600 |

0.8~2.0 |

2200 |

1300 |

2100 |

|

FTBS-50 |

45 |

50 |

3~18 |

2~2.5 |

100~1000 |

0.8~2.0 |

2500 |

1400 |

2200 |