Z Channel Roll Forming Machine

2

Share

TECHNICAL PARAMETER

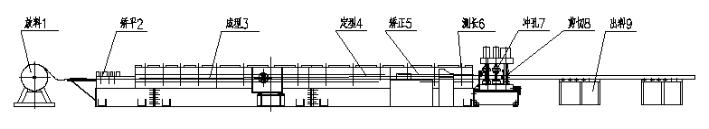

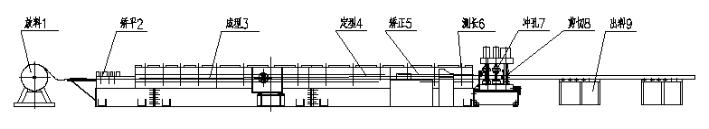

FLOW CHART

FLOW CHART

APPLICATION

APPLICATION

This machine is full-automaticaIly controlled by PLC,the whole hydraulic transmission,drive hydraulic oil jar carry out and shear through centre pump station towards the hole,hydraulic pressure motor transmit power as main transmission,characteristic its reliable for to operate steadily by hydraullc pressure,Shear towards hole precision high,high output,low energy consumption,Section geometry form rule of the notch.Its hydraulic pressure trausmission,two sets of rectification correct and fit,the cut- off have a national patent.

1) Base of machine is processed by planning machine and the locating pin of screw connects wall of machine stand. Panel can be formed with straightness, which guarantees the high accuracy.

2) Adopts hydraulic interlaced cutting which makes sure of the exact geometrical profile of formed panel. This cutting method causes no waste material.

3) Computer for measuring the length, hydraulic punching for the long holes at both sides and round holes in the middle, the distance between holes can be adjusted.

4) Arranges with leveling unit of 7 rollers, which assures the levelness of Z purlin.

5) Material of roller adopts high-quality alloyed GCR15

6) Craft of heat treatment: forging — temper — anneal — normalizing — quenching -- temper

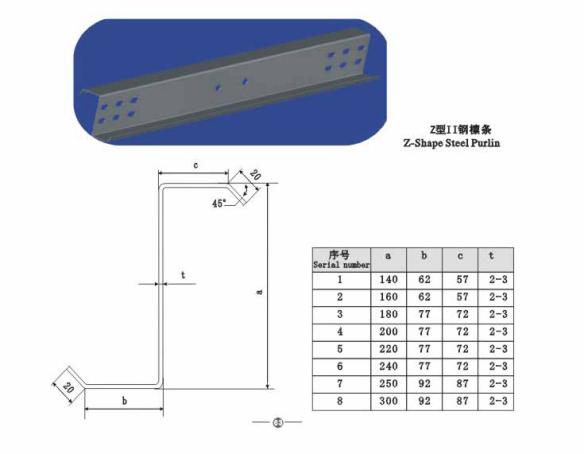

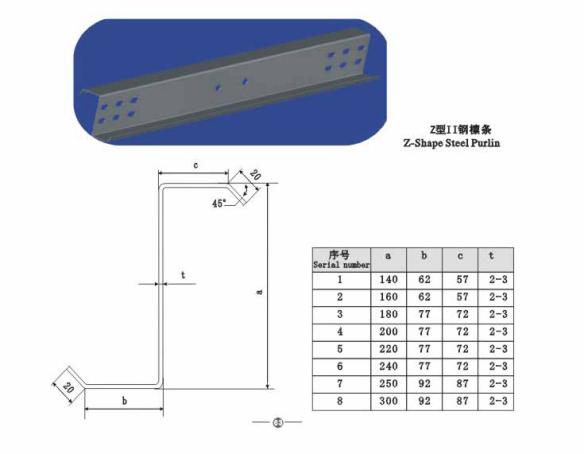

7)Sizes of product:width(a):140, 160, 180, 200, 220, 240,250, 300

height(b):62, 77, 92

8)Diameter of roller shaft: ¢70㎜

9) Length of production line: 20m

10) Forming speed: 0-18m/min

11) Quenching hardness of roller: HRC580-600

12) Quenching deepness of roller: 8mm

13) Thickness of steel coil: 2.0-3.0mm

14) Total motor power: 22kw

15)Power source:380V / 3 phases / 50Hz

16)Computer adopts PLC,Omron CPEE-N30DR according to customer

17) Computer operating board adopts Xinjie OP320A

18) Roller station: 15 stations

19) Decoiler type: umbrella type

20)Weight capacity of decoiler:5T

PROFILE

1) Base of machine is processed by planning machine and the locating pin of screw connects wall of machine stand. Panel can be formed with straightness, which guarantees the high accuracy.

2) Adopts hydraulic interlaced cutting which makes sure of the exact geometrical profile of formed panel. This cutting method causes no waste material.

3) Computer for measuring the length, hydraulic punching for the long holes at both sides and round holes in the middle, the distance between holes can be adjusted.

4) Arranges with leveling unit of 7 rollers, which assures the levelness of Z purlin.

5) Material of roller adopts high-quality alloyed GCR15

6) Craft of heat treatment: forging — temper — anneal — normalizing — quenching -- temper

7)Sizes of product:width(a):140, 160, 180, 200, 220, 240,250, 300

height(b):62, 77, 92

8)Diameter of roller shaft: ¢70㎜

9) Length of production line: 20m

10) Forming speed: 0-18m/min

11) Quenching hardness of roller: HRC580-600

12) Quenching deepness of roller: 8mm

13) Thickness of steel coil: 2.0-3.0mm

14) Total motor power: 22kw

15)Power source:380V / 3 phases / 50Hz

16)Computer adopts PLC,Omron CPEE-N30DR according to customer

17) Computer operating board adopts Xinjie OP320A

18) Roller station: 15 stations

19) Decoiler type: umbrella type

20)Weight capacity of decoiler:5T

Products

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material

TOP