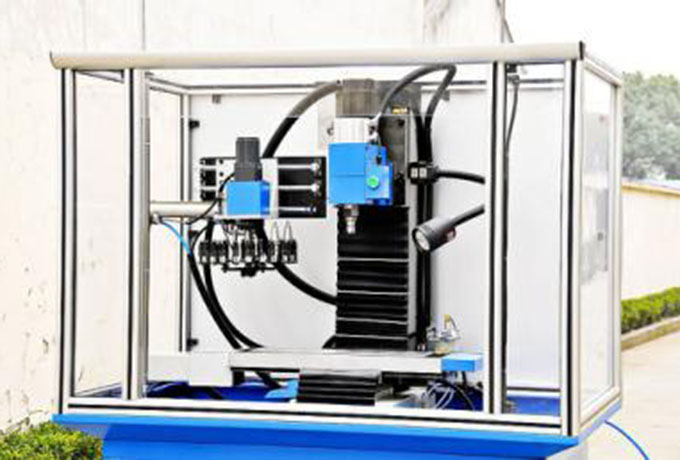

•2 tools ATC

•Transparent enclosure

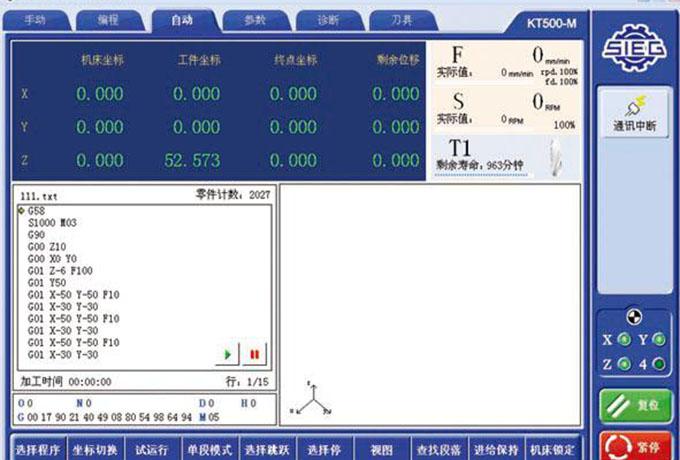

•PC-Based CNC system,high reliability

•Pre-installed 4axis fast interface

•Pre-installed hand wheel controller fast interface

•Best for small production and education training

|

TABLE |

Table size |

550×160mm |

|

|

T slot (amount×width×distance) |

3×12mm×43mm |

|

|

Max. load |

30kg |

|

TRAVEL |

X travel |

270mm |

|

|

Y travel |

152mm |

|

|

Z travel |

270mm |

|

|

Spindle nose to table |

80-350mm |

|

|

Spindle center to column |

215mm |

|

SPINDLE |

Spindle taper |

ISO20 |

|

|

Spindle motor |

1000W |

|

|

Spindle speed |

100-5000r/min |

|

FEED |

Rapid feed |

5000mm/min |

|

|

Cutting speed |

1000mm/min |

|

|

Power of X/Y |

400W |

|

|

Power of Z |

750W |

|

FEED |

The max moving speed |

2000mm/min |

|

|

The max feeding speed |

500mm/min |

|

|

Power of X/Y |

4Nm |

|

|

Power of Z |

6Nm |

|

TOOL |

Tool number |

12 |

|

|

Max.tool diameter |

10mm |

|

|

Max.tool length |

110mm |

|

|

Max.tool weight |

0.5kg |

|

|

Time of tool changing |

8s |

|

ACCURACY |

Positioning accuracy |

0.01mm |

|

|

Repeatability accuracy |

0.01mm |

|

OTHERS |

Pneumatic supply |

0.6 MPa |

|

|

Power |

230V/120V |

|

|

Weight(NW/GW) |

390×470kg |

|

|

Overall dimension |

1280×895×1845mm |

|

|

Packing size |

1420×1060×2035mm |

Successful cases:

Our iKX3 comes with 12 ATC, ISO20 spindle type, 5000rpm spindle speed. Pneumatic control will lead to the tool changing easily. Servo motors will bring higher speed and accuracy. It is very popular in educational market, especially in US. There are two enclosure for choice, iron encosure and transparent enclosure. Students could see the operation from different views.

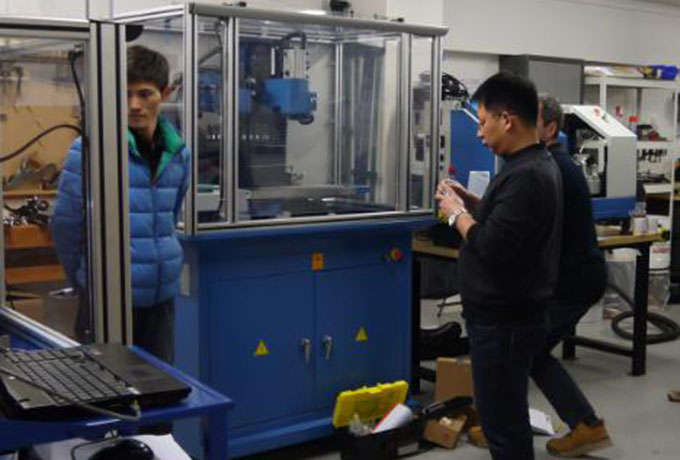

Our customer in UK have a training room for our machines, iKX3-SIEG is one of them . They have a very professional team that can train customers in the training center.

Here is the link from our dealers:

UK:http://www.axminster.co.uk/axminster-cnc-technology-ikx3-mill

Czech: http://www.bow.cz/produkt/7513003-cnc-frezka-ikx3/

More details for your reference:

Click to view Optional Accessories

Click to view Optional Accessories SIEG system

SIEG system  Iron enclosure

Iron enclosure Transparent enclosure

Transparent enclosure  iKX3 production in our factory

iKX3 production in our factory