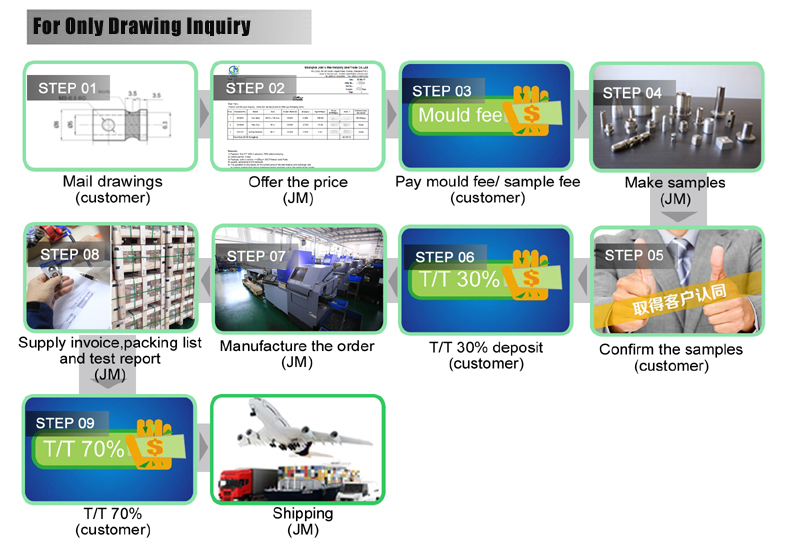

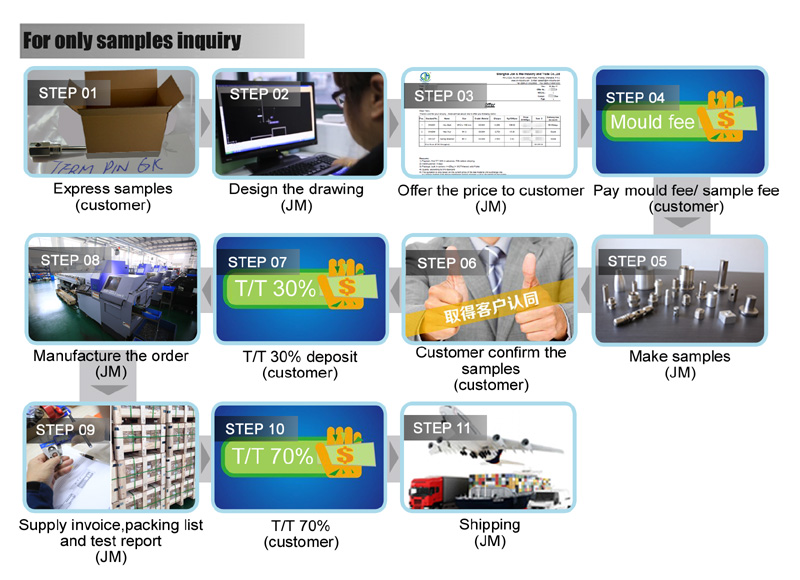

JM can design and manufacturing special products according to the drawings or samples for your requirements

|

|

|

|

|

JMCAP-001 |

JMCAP-002 |

JMCAP-003 |

|

|

Custom Carbon Steel Assembly Part |

|

|

|

|

|

JMCAP-004 |

JMCAP-005 |

JMCAP-006 |

|

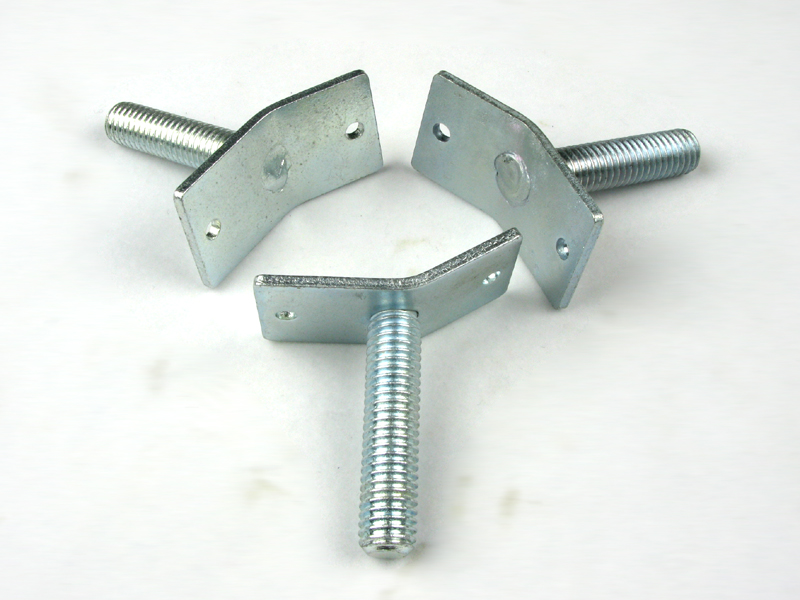

Stamping Parts with T Bolts and nuts |

Stamping Parts with Pan head screw & Plastic Part |

Stamping Assembly Parts |

|

|

|

|

JMCAP-007 |

JMCAP-008 |

JMCAP-009 |

|

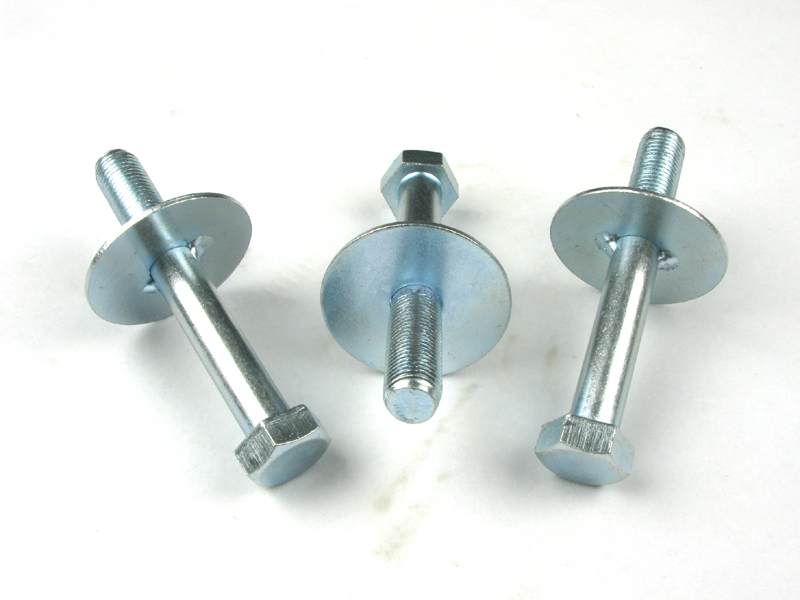

Hex Bolt Assembly Part |

Stud Bolt Assembly Part-1 |

|

|

|

|

|

JMCAP-010 |

JMCAP-011 |

JMCAP-012 |

|

Stainless Steel Assembly Part |

Stud Bolt Assembly Part-2 |

|

|

|

|

|

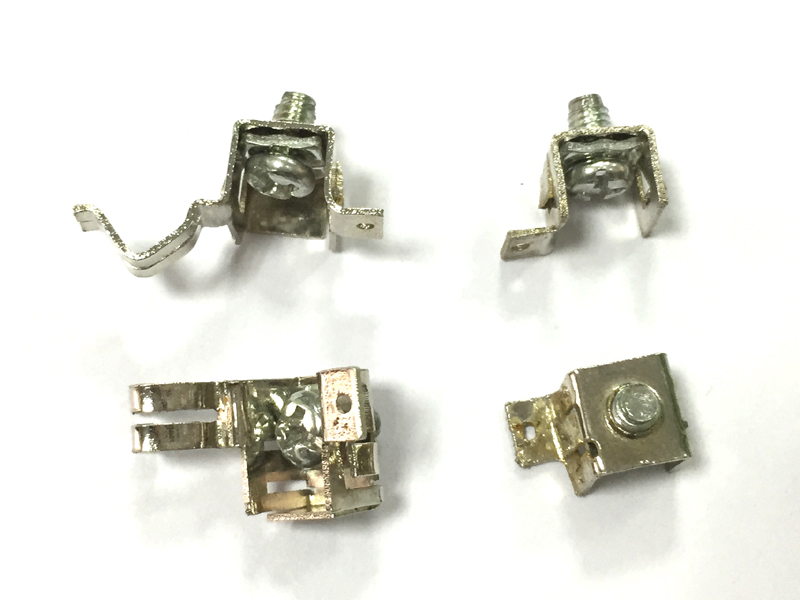

JMCAP-013 |

|

|

|

Electrical Contact System (Nickel-Plated Assembly Part) |

|

|

|

Product Feature: |

High Surface Finish; Uniform coating thickness; High tensile strength(>600); Excellent atmospheric corrosion resistance,welding and cold forming performance; Leaf-shaped crystalline pattern; Beautiful Designed |

|

Materials: |

stainless steel, iron ( SPCC, SECC, SPTE, tinplate), aluminum alloy, red copper, brass, bronze alloy are available. |

|

Processing Craft: |

Laser Cutting, CNC Punching, CNC Bending, Tig Welding, Mig Welding, Riveting, Grinding, Stamping; |

|

Surface Finished: |

Powder Coated, Hot Galvanized, Painting, Polishing, Brushing, Cataphoresis, Chrome/Zinc/Nickel Plating/Anodize/Electronic Polish, Silk-screen etc; |

|

Major Equipment: |

TRUMPF LASER CUTTING MACHINE; |

|

CNC SHEAR MACHINE; |

|

|

CNC PUNCHING MACHINE; |

|

|

CNC BENDING MACHINE; |

|

|

TIG WELDING MACHINE; |

|

|

MIG WELDING MACHINE; |

|

|

SPOT WELDING MACHINE; |

|

|

STAMPING MACHINE; |

|

|

ROLLING MACHINE; |

|

|

PIPE BENDER; |

|

|

Serve Type: |

OEM,ODM; |

|

Files Formats: |

Pro/Engineer, Solidworks, Auto CAD |

|

Certification: |

ISO9001:2008; |

|

Application: |

Appliance/ Automotive/ Agricultural Electronics/ Military/ Marine/ Mining/ Hydraulics/ Valves/ Oil and Gas/ Electrical/ Construction/ machinery/ furniture/ LED/ woodboard/ wall etc |