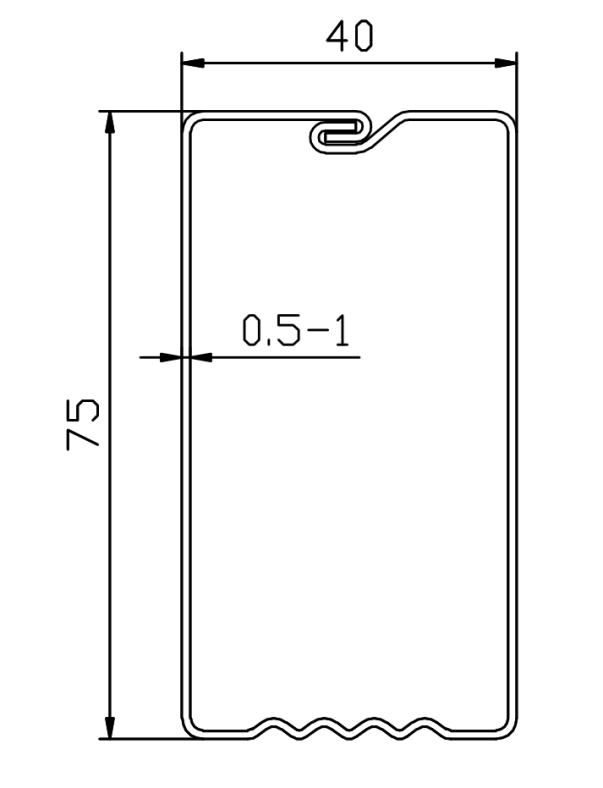

1.Material Specification :0.48-1.0mm GI sheet,Strength yield≤550mpa

2.De-coiler mode:3T manual de-coiler

3.Main motor power:7.5KW

4.Working speed:10-15mm/min

5.Roller steps:16 horizontal rollers and a series of vertical rollers.

6.Main shaft diameter:70mm

7.Machine structure:Wallboard type,single row 1.2 inches chain drive

8.Roller material:High quality GCR15 quenching treatment HRC 58-62. The rollers after quenching treatment and do the secondary processing, which can guarantee the roller accuracy and remove the rollers deformation after quenching treatment.

9. Control system:Panasonic PLC control system

10.Machine rack uses 450U-steel, location on two sides.

11.Cutting mode:flying saw following cutting mode after forming

B Production technology process

De-coiler ---- guide feeding ----- forming ----- Sizing(3 rollers + rotation)--- Die press out ----flying saw following cutting ---- output

-

Roll forming machine

- CZ Purlin Roll Forming Machine

- Roof Sheet Roll Forming Machine

- Wall Sheet Roll Forming Machine

- Drywall Stud Track Roll Forming Machine

- Strut Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- Cable Tray Roll Forming Machine

- Steel Silo Roll Forming Machine

- Racking Shelf Roll Forming Machine

- Store Plate Roll Forming Machine

- Square Tube and Round Tube and Pipe Roll Forming Machine

- Gutter Roll Forming Machine

- K-span Roll Forming Machine

- Other Special Shape Roll Forming Machine

- Sandwich Panel Line

- Slitting and cut to length line

- Auxiliary machine

- Folding container