Brine Treatment Evaporator

High saline water treatment solution

Introduction

The structure of the brine evaporator and the horizontal shell tube condenser is basically similar, according to the liquid supply way can be divided into shell tubes evaporator and dry evaporator two kinds. The horizontal shell and tube evaporator are widely used in closed saline water circulation system.

Main Characteristics

compact structure, good contact between liquid and heat transfer surface, high heat transfer coefficient. But it needs to be filled with a large amount of refrigerant, and the liquid column will have a certain effect on the evaporation temperature. And when the brine concentration is reduced or the salt water pump is shut down for some reason, the brine is frozen in the tube. If the refrigerant is freon, the dissolved lubricating oil in the freon is difficult to return to the compressor. In addition, the cleaning should be stopped when cleaning. The main difference of dry freon evaporator is that the refrigerant flows in the tube, while the refrigerant flows outside the tube. After throttling the freon liquid enters the evaporator from the lower part of one side end cover, after several processes, from the upper part of the end cover, the refrigerant is evaporated in the tube with the flow, so the wall has a part of the vapor possession, therefore, the heat transfer effect is not as good as the liquid type. However, it has no liquid column on the evaporation temperature, and because of the higher flow rate of freon ( ≥ 4 m / s ), the oil return is better. In addition, the risk of freezing is mitigated by a large number of cold - carrying agents being charged outside the tube. The refrigerant charge in this evaporator is only 1 / 2 ~ l / 3 or less of the liquid type, so it is called " dry evaporator ".

Application Range

The solution for wastewater evaporation and crystallization, brine management, high salinity water treatment, desalination, ZLD system etc.

System components

Evaporator, separator, condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc.

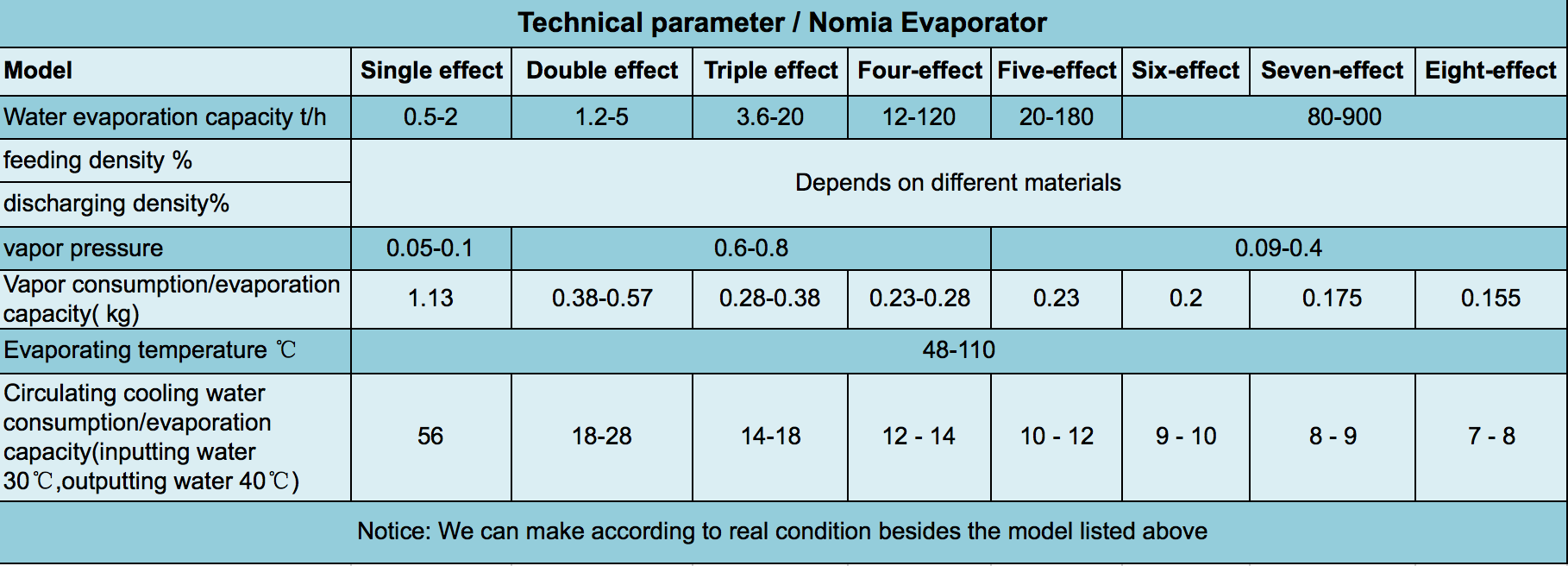

Multi-effect evaporation concentration technology

The Live steam as the thermal energy for heating the first effect evaporator then generates secondary vapor which drawn into the second effect evaporator and so on. The multiple evaporators attached to form the whole multiple effect evaporation system. The latent heat will be recycled and reused, thus reducing the energy consumption and enhance thermal efficiency.

Technical parameter

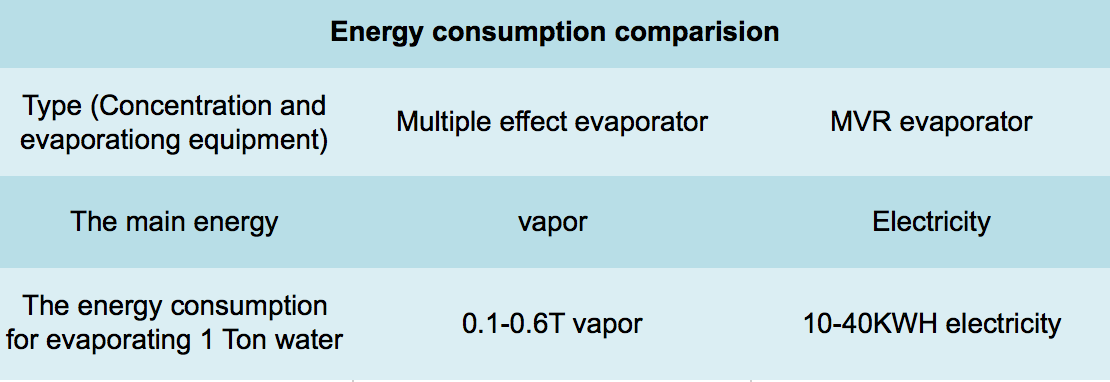

Energy Consumption