Sugarcane juice Evaporation and crystallization system

System Introduction

Rising film Evaporation Crystallization System are wildly used, Raw material liquid and circular mother liquor are pumped to heater for heating, and then enter into the FC crystallization system, Part of the crystal slurry discharged from the conical bottom of the crystallizer, and others are pumped to the crystal room through circulating pump again,recycle and continuous crystallization process.

This crystallizer can improve heat transfer effect, which has effective for high density and high viscosity solutions; High capacity; Suitable for high salt wastewater evaporator crystallization process, which the composition is complicated and have low requirement for the salt particle.

Features

- Low requirements for the material properties, flexible for the operation

- Axial type feeding, to improve the crystallization effect

- Flow velocity in heating tubes, to improve tube wall scaling

- The design of the Oslo evaporation crystallizer can distinguish the supersaturation generate area with crystal growth area, Under the action of circular mother liquor, the crystals can form the crystal granularity classification of fluidization effect in the growth area and can make the larger size crystal abdominal muscle discharging from the bottom of the crystallizer. This kind of crystallizer can screen crystal particle size, Suitable for the material of simple crystal component, good liquidity and the materials which have high requirements of salt quality.

- Large circulation flow rate,low-degree supersaturated solutions, not easy to produce a secondary crystal nucleus which helpful for crystallization operation.

- Crystals will not be broken through clear liquid circulation.

- The crystals produced by the Oslo Crystallizer are large and homogeneous.

Application Range

Salts crystallization, cane sugar crystallization, starch production, saline wastewater treatment, brine management, high salinity water treatment, desalination, ZLD system etc.

System components

Evaporator, separator(crystallizer), condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc.

Multi-effect evaporation technology

The Live steam as the thermal energy for heating the first effect evaporator then generates secondary vapor which drawn into the second effect evaporator and so on. The multiple evaporators attached to form the whole multiple effect evaporation system. The latent heat will be recycled and reused, thus reducing the energy consumption and enhance thermal efficiency.

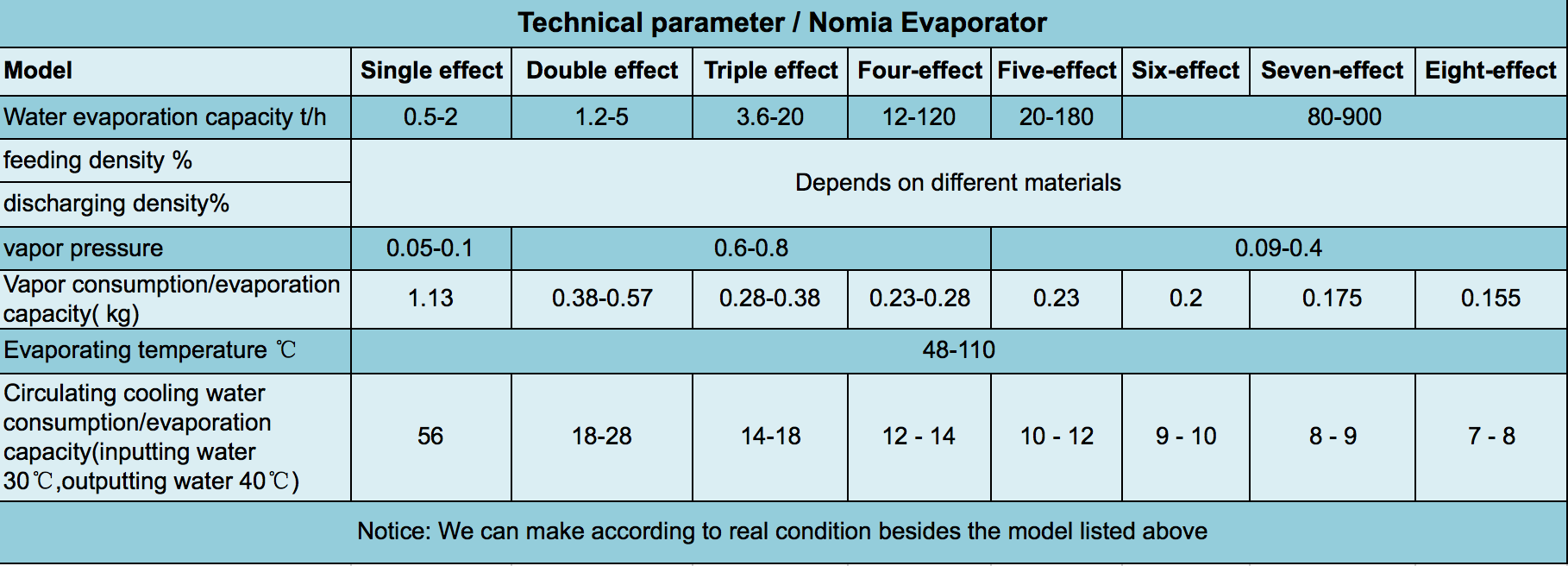

Technical Parameter

Detailed photos

Evaporator selection notice

- 2. MVR invest more than multi-effect evaporator at the early stage, but the cost shall be covered after 300days service.