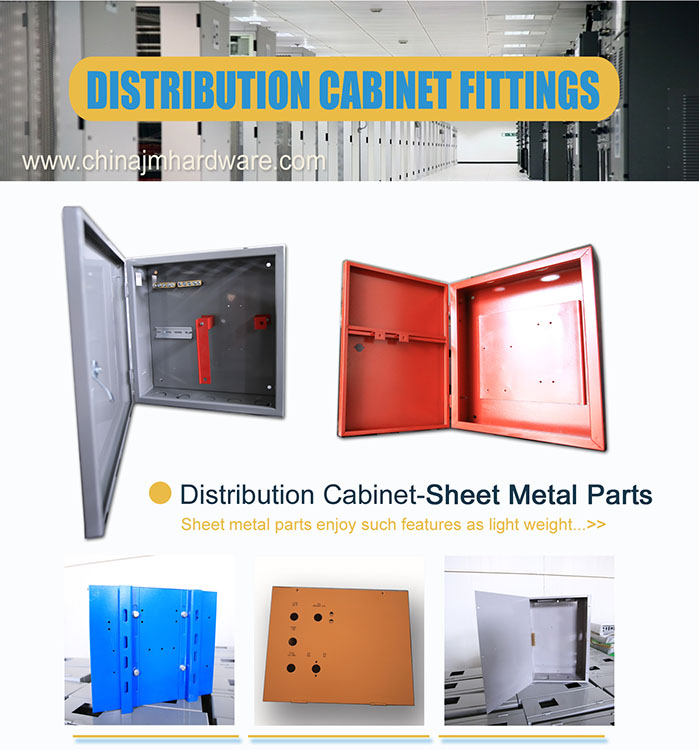

Distribution box is divided into welded box and assembled box

.Distribution box is mainly used for control of electrical equipment, power distribution, overload of the line, short circuit, leakage protection. Distribution box installed in various places, such as schools, offices, hospitals, factories, workshops, families, such as lighting distribution boxes, power distribution boxes. Small distribution box, can be darkly set in the wall, you can stand on the ground.

Common sizes are: height 2200mm, width 600mm, 800mm, 1000mm three, three different width dimensions each have a depth of 600mm, 800mm, 1000mm.

As a Professional sheet metal fabricators in sheet metal fabrication field in China. JM use composite mold, especially multi-level progressive die, to produce various types of precision stamping parts, box sheet metal parts, and large cold parts. We can process carbon steel plate, stainless steel plate, aluminum plate, copper and other materials.

All of the products we designed and processed based on customer drawings or samples.

|

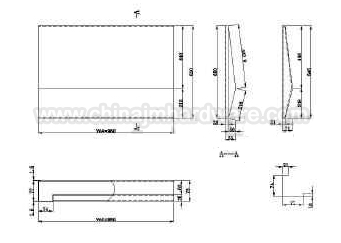

Size: |

Customized. We need your drawings in CAD, 3D or PDF. Or you send us your sample, we draw for you. |

|

Surface treatment: |

Blacking, polishing, anodize, chrome plating, nickel plating, tinting, Powder coating, spray coating, paint, electroplate, Brushing, Galvanize, Silk screen, laser engraved etc. |

|

Color: |

Customized |

|

Application: |

Appliance/ Automotive/ Agricultural Electronics/ Military/ Marine/ Mining/ Hydraulics/ Valves/ Oil and Gas/ Electrical/ Construction/ machinery/ furniture/ LED/ woodboard/ wall etc |

|

Material: |

SPCC,SECC,SHCC,Aluminum,201SS,304SS,316SS,430SS,Copper etc. |

|

Processing Craft: |

Laser cutting, CNC punching, CNC bending, Tig welding, Mig welding,Riveting,Grinding,Stamping etc. |

|

Drawings Format: |

Solidworks,Pro/Engineer,AutoCAD,PDF,JPGE,PNG etc. |

|

Service Type: |

OEM&ODM |

|

Tolerance: |

±0.1mm |

|

Extra Service: |

CAD Design Services |

|

Stamping Equipment: |

TRUMPF LASER CUTTING MACHINE; |

|

CNC SHEAR MACHINE; |

|

|

CNC PUNCHING MACHINE; |

|

|

CNC BENDING MACHINE; |

|

|

TIG WELDING MACHINE; |

|

|

MIG WELDING MACHINE; |

|

|

SPOT WELDING MACHINE; |

|

|

STAMPING MACHINE; |

|

|

ROLLING MACHINE; |

|

|

PIPE BENDER; |

production process

Shanghai Jian & Mei Stamping Factory offers a variety of precision punch, CNC punch, CNC folding machine, laser cutting equipment, oxygen cutting equipment and all kinds of welding equipment.

JM use composite mold, especially multi-level progressive die, to produce various types of precision stamping parts, box sheet metal parts, and large cold parts. JM can process 0.5-200mm sheet material and provide a variety of surface treatment: galvanized, polishing, electrophoresis, spray, nickel, paint, Dacromet and so on. We can process carbon steel plate, stainless steel plate, aluminum plate, copper and other materials. All of the products we designed and processed based on customer drawings or samples. We provide OEM & ODM services to our customers.

JM is in strict accordance with the ISO9001: 2008 system for production management. All products and materials are tested and managed under rigorous procedures, each process is self-tested on a regular schedule and tested and inspected before each shipment. After the final inspection, the product will hand to the packaging process. We will package the products according to the customer's requirements, and choose the appropriate packaging materials, then ship to the destination.

|

Stamping parts |

|

|

Surface Treatment: |

Blacking, polishing, anodize,geomet, chrome plating, zinc plating, nickel plating, tinting, Powder coating, spray coating |

|

Materials: |

Aluminum Alloy: |

|

5052 /6061/ 6063 / 2017 / 7075 / etc. |

|

|

Brass Alloy: |

|

|

3602 / 2604 / H59 / H62 / etc. |

|

|

Stainless Steel Alloy: |

|

|

303 / 304 / 316 / 412 / etc. |

|

|

Steel Alloy: |

|

|

Carbon Steel / Die Steel / etc. |

|

|

Other Special Materials: |

|

|

Lucite / Nylon / Bakelite / POM / PP / PE / PC / Titanium / ABS etc. |

|

|

We handle many other type of materials. Please contact us if your required material is not listed above. |

|

|

Stamping Equipment: |

TRUMPF LASER CUTTING MACHINE; |

|

CNC SHEAR MACHINE; |

|

|

CNC PUNCHING MACHINE; |

|

|

CNC BENDING MACHINE; |

|

|

TIG WELDING MACHINE; |

|

|

MIG WELDING MACHINE; |

|

|

SPOT WELDING MACHINE; |

|

|

STAMPING MACHINE; |

|

|

ROLLING MACHINE; |

|

|

PIPE BENDER; |

|

|

Mould type: |

Progressive die, single press mould, transfer mould, etc. |

|

Application: |

Aerospace, Automotive, Electrommunication, Medical, Household Appliances, Furniture industry, Machinery industry, instrument and meter |

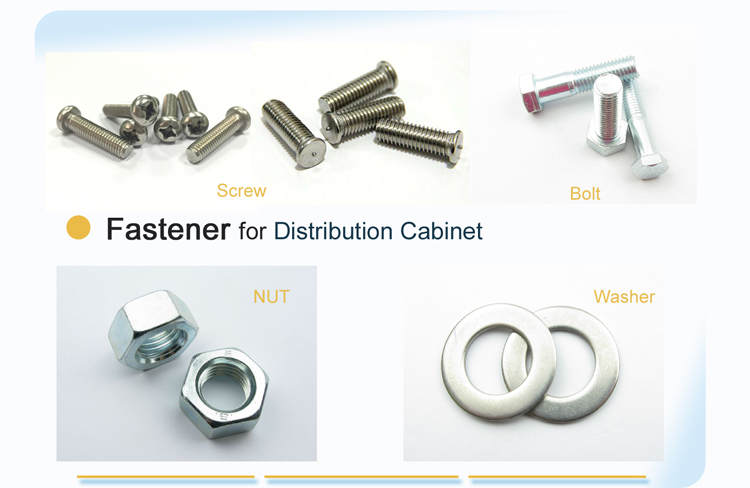

In distribution cabinet fittings, commonly used standard fasteners include:

- Rivet screw, Pan cross slot machine screws

- Hex bolt

- Hex flange bolt

- hex nut

- hex flange nut

- flat washer

- spring washer