01:23

01:23

Description Tetris Space building is made by a range of modules. Each module adopts either the shipping container or light gauge steel structural system with different types of renovative environmental materials, which is produced from the production line. This product can be stand-alone or combined verticallly and horizontally to create the modular complex buildings. According to the structural system, there are CONTAINER STRUCTURAL SYSTEM BUILDING and LGS STURCTURAL SYSTEM BUILDING two major series. The architectural, structural, electrical, drainage and decorative works of each module are premanufactured in the factory, and transported to the construction site as complete modules, then by using the crane to lift to exact position to finish the final assembling. This product is widely used in residential, industry, commercial and public service area as the hotels, apartments, offices, supermarkets, educational facilities, government settlement housing, tourist spots, military camp and etc. Advantages Highly prefabricated, short constructin period - Tetris Space is one of the most prefabricated products in the modular field. After fully documented and produced in the factory, transferred to construction site to be assembled mechanizedly. The production cycle is much less than the tranditional types of buildings, and every step is pre-scheduled and foreseeable. Line production, low cost - Each module comes from the production line, thus the quality is strickly controlled and the production efficiency is very high, so the manufacturing cost is reduced to minimum. Functional usage, suitable for all - Each module can be designed and made as office, accommodation, lounge, bathroom, kitchen, dining, gym, recreation, clinic, laundry, storage and other different spaces based on clients' inquiries. High stability, durable life time - The structural systems have been tested by many authorities to ensure the stability and safety of the buildings. They have long service life time and high seismic resistance, crushing resistance, sound insulation performance, thermal performance, fire resistance, water resistance and windproof performance. According to the different regulations and needs of different areas or inquiries, this product can be made as permanent or semi-permanent buildings. Various combinations, great livability - By using different ways of combining modules and materials to create different types of architectural space and facade appearance. The maximum sizes of single module our factory can produce is 16154mm long, 4600mm wide and 3300mm high, which has covered up most sizes of required demands in the world, and gives the designers more flexibility. Integral module, easy for transporting and assembling - Each module is an integrality, which is easy for transporting by road, railway or ship freights. Compare with other prefab buildings, it has less packaging cost and time.

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:15

01:15

Description • Limited budget • Tense construction time • Various floor layouts • High-standard aesthetic requirements The upgraded EASY HOUSE (Prefab house) series are designed, based on the traditional portable panel buildings by adopting the same structure and basic materials, to solve all the issues above. This product adopts the light gauge steel as the structure, the renovative wall panels as the enclosure components and the cladding and different types of paints as the finishing material while is using the standard modular system to arrange the layout. The main structure can be assembled by bolts to achieve the fast and easy erection. Different proposals of structural systems, material selections, exterior appearances, floor plans are provided according to the development levels, weather conditions, living habits and cultural background of different areas, to meet the requirements of different people. Advantages Attractive Appearance Variouslayouts are easily formed by using the standard modularity, and the appearances and colours of the facades and the locations of window and door are adjustable to satisfy particular requirements for people from different backgrounds. Affordable & Practical According to the different levels of economic development and the weather conditions, different options of budget and design are available. Great Durability Under normal circumstances, the EASY HOUSE (Prefab house) has long performance life for over 20 years. Easy Transporting Limited onsite work, averagely every four experienced workers can erect approximately 80m2 main structure of EASY HOUSE every day. Fast Assembling Limited onsite work, averagely every four experienced workers can erect approximately 80m2 main structure of EASY HOUSE every day. Environmental Friendly Each component is pre-manufactured in the factory so the onsite construction rubbish is reduced to the minimum, very economy and environmental friendly.

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:10

01:10

Description Basically, there are two types of construction methods of Yahgee Domus (Light Gauge Steel House). One is called LGS-style Yahgee Domus, which is using light gauge steel as the structural frame and adopting the glass wool or rock wool as the thermal material, the internal and external wall panels are installed on site; the other is using profiled steel as the structural frame, and finished by the factory prefab wall panels, which are transported and assembled as complete pieces on site; thus this type is called Panel-Style Yahgee Domus.. The most common wall panel materials for the second construction method are fiber cement board, OSB panel, plaster board, ALC panel, GRC panel and etc. There are many optional materials available for the internal walls, external walls and roof tiles of the Yahgee Domus, to satisfy different inquiries for different clients. The complexity designs of layout and facade to satisfy people from different background or with different artistic taste can be easily achieved according to the various options of construction methods of Yahgee Domus. This type of buildings has over 50-year service lifetime, because of the durably structural and decorative materials, which has been approved by the western countries. Luxury, elegance and aesthetics are the first expression of the Yahgee Domus to people. Comfort, durability and safety are the second expression of the Yahgee Domus to people. Advantages Some of the main properties of LGS are as follows: • Lightness in weight • High strength and stiffness • Ease of prefabrication and mass production • Fast and easy erection and installation • Substantial elimination of delays due to weather • More accurate detailing • Non shrinking and non creeping at ambient temperatures • Termite-proof and rot proof • Economy in transportation and handling • Non combustibility • Recyclable material Note: We have no inventory, no retail business, we we provide customized wholesale business.

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:08

01:08

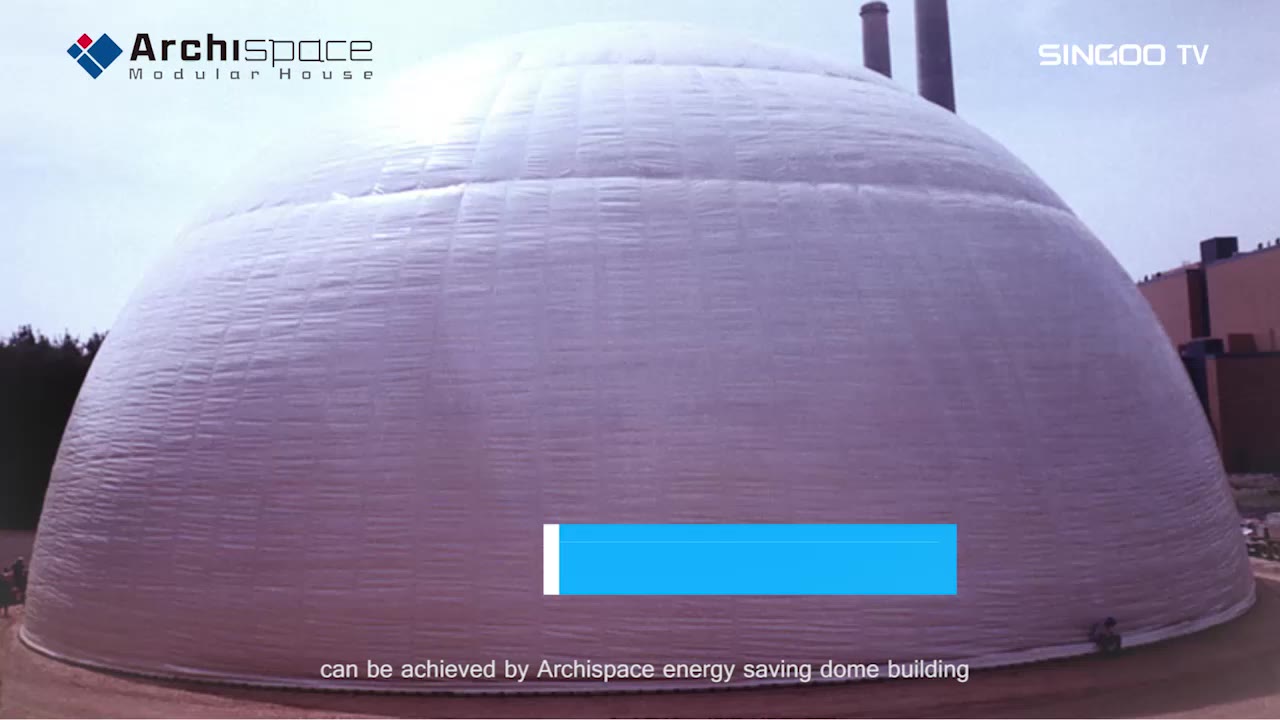

Characteristics 1、Pure-green construction without any beam and column 2、USA patent,warm in winter and cool in summer,power saving,no leaking and insect resistance 3、Short construction period,various model change 4、RC structures as permanent construction 5、Hurricane resistance and anti-seismic(mainly use in school and refugee shelter) 10 advantages 1. High tension intensity 2. High thermal-insulation efficiency 3. Good fire-proof performance 4. Good leaking proof performance 5. Good insect resistance 6. Good performance of hurricane resistance 7. Strong capability of anti-seismic 8. Lower construction cost 9. Lower operating cost 10. Lower maintenance cost Applications ●Hall & Theatre ●Disaster Relief ●Hotel & Apartment ●School ●Tourist ●Commercial Building ●Exhibition

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:22

01:22

Specifications and Sizes: Product name Marble Coating Aluminum Composite Panel Aluminum Alloy AA1100, AA3003, AA5005 Al sheet thickness From 0.25mm*0.25mm to 0.5mm*0.5mm Panel thickness From 3mm to 6mm Panel width 1000mm & 1220mm & 1250mm & 1500mm & 1575mm Panel length Upon customs' request Color Upon customs' request Service OEM and ODM are available Standard ACP size is 1220 * 2440mm * 4mm. Customized size is also available. Aluminum Composite Panel Applications: A Building exterior curtain walls B Decoration and renovation additions for old buildings C Decoration of interior walls, ceilings, bathrooms, kitchens and balconies D Shop door decorations E Advertisement board display platforms and signboards F Wallboard and ceilings for tunnels Details: Aluminum Source: South West Aluminum Factory Painting Source: PPG&BECKER PE core Material: Non-toxicand low-density Polyethylene Payment Term: TT, LC at sight,D/P,Western Union,Paypal Production Capability: 250000SQM/Month More Service: OEM, Samples free(samples will be sent in one day time ) Applications: A. Building exterior curtain walls B. Decoration and renovation additions for old buildings C. Decoration of interior walls, ceilings, bathrooms, kitchens and balconies D. Shop door decorations E. Advertisement board display platforms and signboards F. Wallboard and ceilings for tunnels Assurance: 1. Goods Inspection: We have professional inspection team to Cooperate with the SGS Laboratory assigned by customer to do the goods inspection. 2. Quality Assurance: We keep the production samples as well as the corresponding test data for customer’s inspection in the future. 3. Goods Return Service: We provide free replacement for goods incompliance with committed quality. 4. Response time: We promise respond to customer goods incompliance report as soon as possible within 24 working hours. Certification: Greenbond has a complete strict quality assurance system, as well as successfully passed ISO 9001 and ISO 2001 certifications. Packing & Delivery Packing Details : packed in bulks or wooden box,suitable for shipping container Delivery Details : It need about 25 days after receiving your deposit Greenbond Technical data: Thickness of coating PVDF paint ≧25 um 26um to 28um Coating Flexibility (T-bend) PVDF paint≦2T 2T Coating Adhesion ≧1 grade for 10*10mm2 gridding test 1 grade Pencil Hardness ≧HB HB Resist Solvent No change for 200 times (MEK) No change Chemical Resistance 5%HCL or 5%NAOH-No change for 24hours No change Boiling Water Resistance coating no tear off for 2 hours boiling no tear off Color difference △E≦2.0(follow color sample) 0.5 Panel Peeling Strength 7 N/mm for 4mm panel with 0.5mm aluminium. skin 7N/mm Impact Test for paint 50Kg.cm impact--paint no split for panel no split Abrasion Resistance(L/Mil) ASTM D968 44 Chemical Resistance ASTM D1308 Appearance: No change Film Adhesion ASTM D3359(Note 1) 5B Detergent Resistance(3%) ASTM D2248 Appearance: No change Stripping Strength(kgf/inch) ASTM D903 18.5 Humidity Resistance (3000hrs,100%RH,100°F) ASTM D2247 Appearance: No change Salt Spray Resistance (3000hrs,5% salt) ASTM B117 Appearance: No change

Greenbond is a specialized manufacturer of aluminum composite panels in China. It’s located in Taixing City, Jiangsu Province, 150km away from Shanghai. With over ten years' efforts, our company has gained great development in producing aluminum composite panels.

Contact Supplier 00:19

00:19

Model Type NRC Punching Rate CM-001 0.7 5% CM-002 0.7 3% CM-003 0.75 2% CM-004 0.75 2% CM-005 0.7 1.5% CM-006 0.7 1.5% CM-007 0.7 2% Products photos

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 00:35

00:35

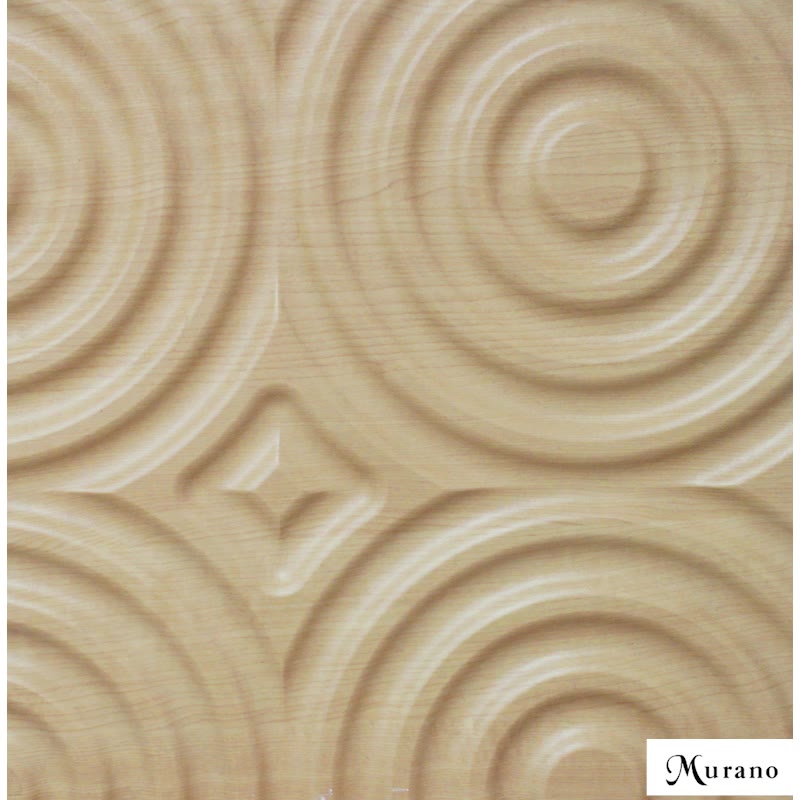

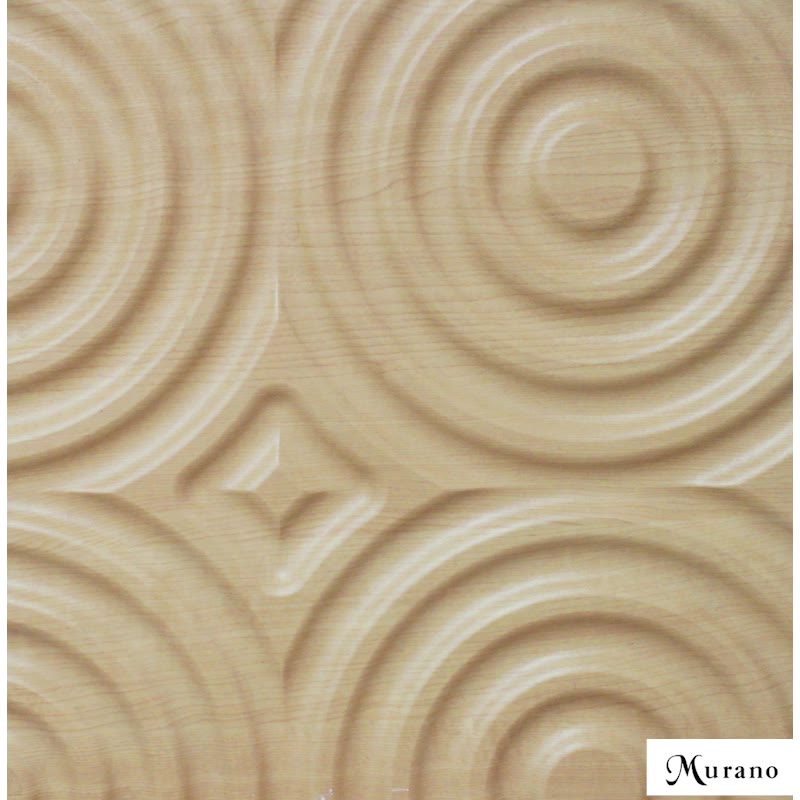

Introduction: MURANO 3D decorative panels are made to the highest standards from high quality MDF with damp proof melamine backing to prevent warping once installed. The 3D carving is carried out on high tech computerized CNC router beds so that every panel matches perfectly when installed. All MDF panels come in primed and sanded smooth finish, making easy work to paint in your choice of color and paint finish. Specification: Material: MDF Dimension: 1200 x 2400mm Thickness: 18mm Finish: Painting/PVC Backing: Melamine Film Density: 760kg/m³

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 00:19

00:19

Specification G8-T3/5 Groove 3mm, Center to Center 8mm Surface Melamine / Woode Veneer / Painting / Fire resistance panel Core 1,MDF core, low formaldehyde with E1 standard 2,ECO core, which is low formaldehyde with E0 standard. 3,MGO core, which is high fire resistance level with A standard. 4,any required core materials could be replaced. Back Soundtex acoustic felt attached on the back of the panels. Noise Reduction Coefficient 0.7 Fireproof grade GB8624 2012 A / B1 Eco-protection grade E0 / E1 Installation aluminum keel and clips, wood frame, gun nail Certification BV,CE,SGS,ISO9001-2008 Test report Eco protction, sound absorption, flame retardant Model Type Specification NRC Punching Rate G8 M-T-2/6-8-15 0.9 2.5% G10 M-T-2/8-10-15 0.9 2% G16 M-T-2/14-16-15 0.9 1.3% G8 M-T-3/5-8-15 0.9 2.5% G16 M-T-3/13-16-15 0.9 2% G32 M-T-3/29-32-15 0.8 0.93% G32 M-T-4/28-32-15 0.8 1.24%

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 00:19

00:19

Specification G32-T3/29 Groove 3mm, Center to Center 32mm Surface Melamine / Wood Veneer / Painting / Fire resistance panel Core 1,MDF core, low formaldehyde with E1 standard 2,ECO core, which is low formaldehyde with E0 standard. 3,MGO core, which is high fire resistance level with A standard. 4,any required core materials could be replaced. Back Soundtex acoustic felt attached on the back of the panels. Noise Reduction Coefficient 0.7 Fireproof grade GB8624 2012 A / B1 Eco-protection grade E0 / E1 Installation aluminum keel and clips, wood frame, gun nail Certification BV,CE,SGS,ISO9001-2008 Test report Eco protection, sound absorption, flame retardant Model Type Specification NRC Punching Rate G8 M-T-2/6-8-15 0.9 2.5% G10 M-T-2/8-10-15 0.9 2% G16 M-T-2/14-16-15 0.9 1.3% G8 M-T-3/5-8-15 0.9 2.5% G16 M-T-3/13-16-15 0.9 2% G32 M-T-3/29-32-15 0.8 0.93% G32 M-T-4/28-32-15 0.8 1.24%

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 00:35

00:35

Introduction: MURANO 3D decorative panels are made to the highest standards from high quality MDF with damp proof melamine backing to prevent warping once installed. The 3D carving is carried out on high tech computerized CNC router beds so that every panel matches perfectly when installed. All MDF panels come in primed and sanded smooth finish, making easy work to paint in your choice of color and paint finish. Specification: Material: MDF Dimension: 1200 x 2400mm Thickness: 18mm Finish: Painting/PVC Backing: Melamine Film Density: 60kg/m³

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 00:35

00:35

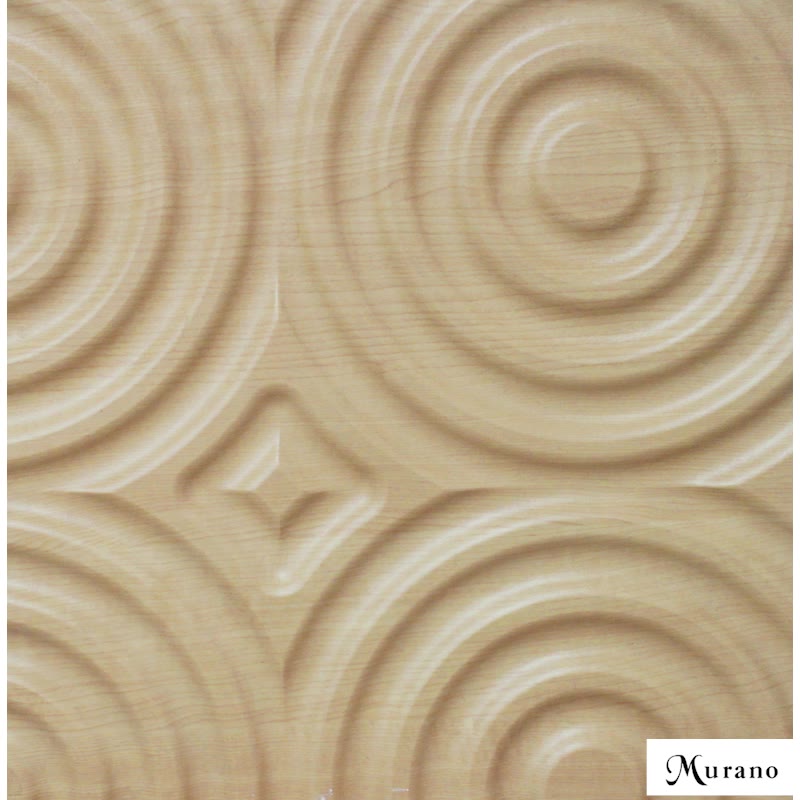

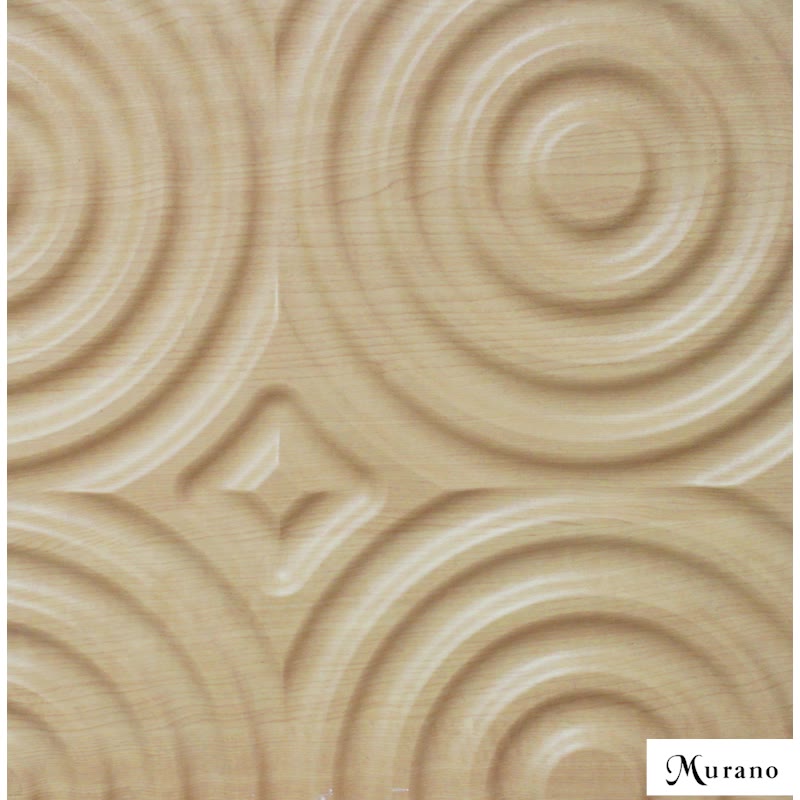

Introduction: Interior Decorative Materials wooden panel the recognized leader in specialty wood ceiling and wall panel systems. We creates exceptional environments utilizing the natural splendor of wood combined with superior decorative performance. Decorative panels delivers quality products at the best value, making it the good choice for interior designers and architects throughout the world. Specification: Material: MDF Dimension: 300*300mm Thickness: 15mm Finish: Painting/PVC Backing: Melamine Film Density: 760kg/m³

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 00:35

00:35

Introduction: Interior Decorative Materials wooden panel the recognized leader in specialty wood ceiling and wall panel systems. We creates exceptional environments utilizing the natural splendor of wood combined with superior decorative performance. Decorative panels delivers quality products at the best value, making it the good choice for interior designers and architects throughout the world. Specification: Material: MDF Dimension: 300*300mm Thickness: 15mm Finish: Painting/PVC Backing: Melamine Film Density: 760kg/m³

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery