01:13

01:13

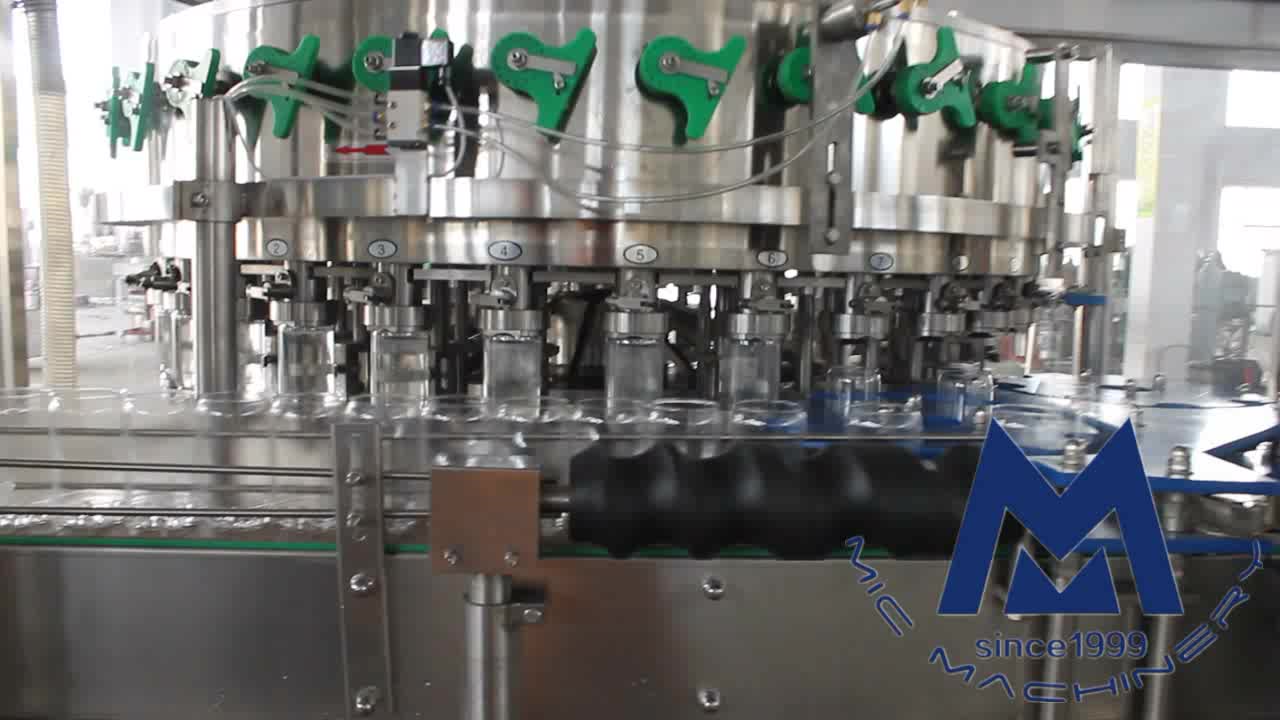

MIC 18-6 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. Recent export news: (click for check news) We sold one to The Republic of Angola on April 25,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:08

01:08

MIC 24-6 It is applicable for can filling seaming machine for energy drinks can package. Adopt products: energy drinks , juice, sugar water, cider, vitamin water, health care drinks etc liquid like juice. Machine working principle: 1. Gravity filling system, controled by gravity, accuracy is +/-1%,liquid level difference is not more than 2mm. easy adjustmeant on liquid level. 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About oxygen content, we have device nitrogen filling for replace air. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, energy drinks filling machine, fruit juice filling machine, vitamin drink filling machine, Vegetables drinks filling machine, healty care drinks filling machine. We sold one to The Federal Republic of Germany on May 2,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:40

01:40

MIC 24-6 It is applicable for can filling seaming machine for juice tea and coffee drinks can package (Hot filling temperature at 85-90 degree) Adopt products: energy drinks , juice, sugar water, cider, vitamin water, health care drinks , coffee etc liquid like juice. Machine working principle: 1. Gravity filling system, controled by gravity, accuracy is +/-1%,liquid level difference is not more than 2mm. easy adjustmeant on liquid level. 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> Pasteurization, inventor and sterilizing tunnel. Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, energy drinks filling machine, fruit juice filling machine, vitamin drink filling machine, Vegetables drinks filling machine, healty care drinks filling machine. The machine is a device developed exclusively by MIC machinery on the basis of digesting and absorbing domestic and international (still) pop can filling and seaming machine (sealing machines). It adopts the normal pressure filling principle. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the customers’ request. It is the preferred equipment for the medium beer and beverage plant

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 02:18

02:18

MIC 18-1 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. We sold one to The Republic Of Poland on April 27,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:13

01:13

MIC 12-1 It is applicable for can filling seaming machine for juice tea and coffee drinks can package (Hot filling temperature at 85-90 degree) Adopt products: energy drinks , juice, sugar water, cider, vitamin water, health care drinks , tea, coffee etc liquid like juice. Machine working principle: 1. Gravity filling system, controled by gravity, accuracy is +/-1%,liquid level difference is not more than 2mm. easy adjustmeant on liquid level. 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> Pasteurization, inventor and sterilizing tunnel. Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, energy drinks filling machine, fruit juice filling machine, vitamin drink filling machine, Vegetables drinks filling machine, healty care drinks filling machine.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:58

01:58

MIC 12-1 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> CIP cleaning system 7> CIP cleaning liquid recycle system 8> Ink date printer (LINX BRAND) Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. Recent export news: (click for check news) →We sold one to the United States of America on May 18,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:19

01:19

MIC 32-8 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Ink printer (LINX BRAND) 7> Can washing machine 8> CIP Clean system 9> CIP cleaning liquid recycle system Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. →We sold one to The Kingdom of Morocco on May 8,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 00:00

00:00

Overview: This hot filling machine is specially made for sticky liquid such as honey,butter,jam,cream,applied to bottles of all sizes,by simple adjustment.It is widely used in food,beverage,cosmetics industries. Quick Details Type: Filling Machine Condition: New Application: Food, Commodity, Medical, Chemical, Textiles Packaging Type: Cans, Bottles, Packaging Material: Plastic, Metal, Glass, Wood Automatic Grade: Automatic Driven Type: Pneumatic/electrical Voltage: 220v/380v/440v Power: 1.5KW Place of Origin: Shanghai, China (Mainland) Brand Name: paixie Model Number: PX2800 Dimension(L*W*H): 1700*980*1650 Weight: 650Kg Certification: CE After-sales Service Provided: Engineers available to service machinery overseas material: ss304/ss316 control: PLC control ,touch screen type: hot filling machine Description: The automatic jam filling machine is developed by our company, customized according to real samples,will be suitable for filling all kinds of high concentrations of fluids.such as jam,butter etc .Driving a piston and transfer--valve’s by air cylinder.Three Contacts principle to extract and to split out the highly concentrated material,8 languages are available on touch screen, adjust the filling volume simply This jam filling machine is simple and reasonable in structure, high precision and simple adjustment.designed by our experienced engineer Pneumatic part adopts Germany FESTO and Taiwan AirTac pneumatic components.stable and durable.we also offer 1 year warranty,and offer all components for free within 1 year. Filling volume and speed can be customized according to production capacity. Connected with capping machine,labeling machine etc to form a whole filling line. CE certificate,ISO9001. General Information Place of Origin:shanghai Brand Name:PAIXIE Model Number:PX-2800 Certification:CE Business Terms Minimum Order Quantity:1 set Price:12000-20000 Packaging Details:strong wooden seaworthy cases Delivery Time:30 days after receiving 30% payment Payment Terms:30% advance payment,70% by T.T Supply Ability:20 sets per month

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:51

00:51

Description: This type of machine is suitable for changing different kind volume of the bottle in one machine line and is widely used in the food, cosmetic, and other industries. It is rather simple and rapid to change spare parts, the design is quite distinct, the property is very advantageous and it is customized and can connect with different kinds machine to form a complete set of produce line. Salient Features: (1) The machine controlled by PLC and touch screen control panel, drive by servo motor, we set several procedures, mode 1, mode 2, mode 3 and so on for different volumes adjustment, easy to operate. (2) Automatic counting the bottles and no bottle no filling. (3) 4.Machine body and the spare parts contacting liquid are made of stainless steel, full compliance with GMP standard. (4) No bottle no filling, the machine will alarm if the bottle is blocked, it also equipped with drip-proof device (5) The machine is easy to disassemble, clean and maintain, and the parts which will contact with the filling materials are made of high quality stainless steel, will meet GMP standard.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview: The machine is in reference to foreign similar products on the basis of improved design, and added some additional functionality. Make the product in the use of operation, accuracy, machine adjustment, equipment cleaning and maintenance more easy and convenient. Widely used in Japan, such as the oil industry, filling different liquid products. The machine is compact and reasonable design, beautiful appearance is concise, the filling quantity convenient adjustment, filling material more quickly and accurately. Adopting Germany FESTO pneumatic components, Taiwan AirTac, SHAKO and Taiwan in electronic components, stable performance. Material contact parts adopt 316 l stainless steel materials. Device that USES Han Guoguang eye, Taiwan PLC, touch screen, frequency converter and electric components, France. Adjustment is convenient, no bottle no filling, filling quantity and accurate counting function. Using drip tight with wire filling cocks, prevent high foam products filling lifting system, to ensure that the bottle mouth positioning of the positioning system and liquid level control system. Feature: Our liquid filling machine adopt the ss304 and ss316 and it accord with CE and GMP. Our liquid filling machine has no drip to ensure that no pollution .And the filling capacity can be customized and can be changed on the touch screen . Our liquid filling machine easy to operate and realize the full automatic . The filling nozzles are specialized made: anti-drop. Also, the filling nozzles will come into the bottle bottom, and moving up slowly when filling. Most of the spare parts use the word famous brand .It can keep the good quality of the machine .Our liquid filling machine is more steady and efficient. Our liquid filling machine will good for your future production. After sale service: (1) Long life service (2) One year warranty (3) Offering free parts for one year

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview: This piston type filling machine is ideal for sticky liquid such as honey,liquid soap,shampoo,applied to bottles of all sizes,shapes and material.It is widely used in industries such as food,beverage,cosmetics etc.cost effective and efficient. Quick Details Type: Filling Machine Condition: New Application: Food, Commodity, Medical, Chemical Packaging Type: Cans, Bottles,jars Packaging Material: Plastic, Metal, Glass, Wood Automatic Grade: Automatic Driven Type: Pneumatic Voltage: 220v/380v/440v Power: 1.5KW Place of Origin: Shanghai, China (Mainland) Brand Name: paixie Model Number: PX-2000 Dimension(L*W*H): 1750*900*1650 Weight: 650Kg Certification: CE,ISO9001 After-sales Service Provided: Engineers available to service machinery overseas material: ss304/ss316 control: PLC control ,touch screen type: piston type filling machine Description: The Piston Filling Machines are heavy duty filling powerhouses. They offer precise filling, flexible filling options, and offer multi work shift reliability. Each filing nozzles is made of Stainless steel. Configurations are available in 2, 4, 6, 8, 10 or 12 nozzle ,for different request of filling speed , sanitary stainless steel product cylinders (0.5-1000 dose models), PLC control, simple operation on touch screen. Adopt anti-dripping, which will save your products, and won’t pollute the machine. With automatic detection, container positioning function, no bottle no filling Adopt lifting filling, ensure no bubble Easy disassembled, will be convenient to wash. Can be suitable for all kinds of sizes and shapes by simple adjustment.save labor and cost. General Information Place of Origin:shanghai Brand Name:PAIXIE Model Number:PX-2000 Certification:CE Business Terms Minimum Order Quantity:1 set Price:15000-20000 Packaging Details:strong wooden seaworthy cases Delivery Time:30 days after receiving 30% payment Payment Terms:30% advance payment,70% by T.T Supply Ability:25 sets per month

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:51

00:51

This machine adopts international advanced technology; cover the circle label on the pet bottle. And then hot shrinking to fix on the position which bottle body designated.This machine's structure is compact, and suitable for the production line of different direction and different height. The machinery part adopts combination designing of modularization, and makes the machine reasonable. The height adjustment adopts motor fluctuating; it is convenient to replace the material. The special cutter head designing, make the film-rolling cut more exactly and reliably.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery