00:30

00:30

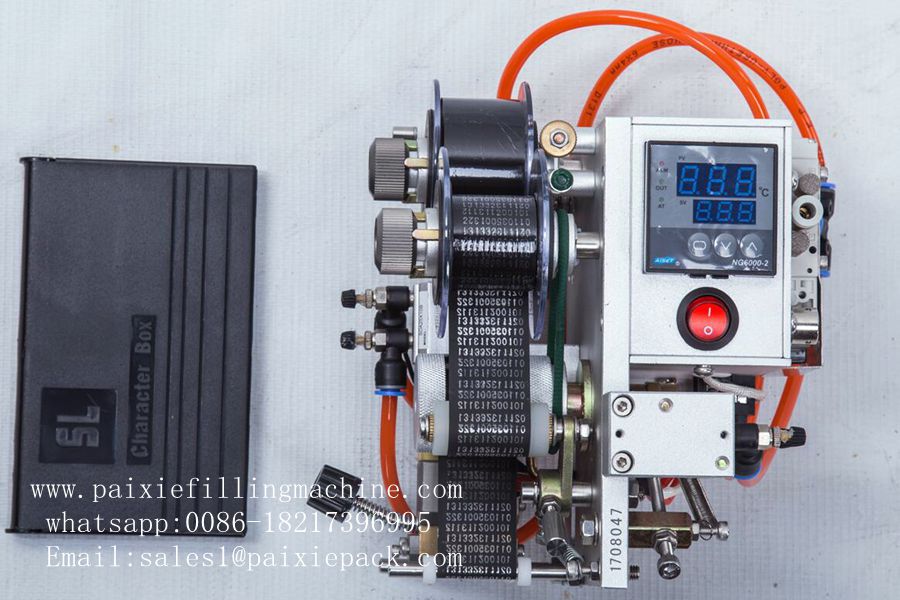

Overview: Hot code printer adopts thermal printing ribbon to avoid oil contamination, which can keep the surrounding clean. It can be used to print notes like production date on the plastic and paper bags in food and pharmaceutical industries. The words printed is clear and endurable against wear. Features: Hot color ribbon code printing machine. The machine is available for both automatic continuously printing code and control by pedal manual. The machine adopt color ribbon printing, has the features of clear printing, easy drying, non sticky, not easy to wipe off. It's able to print code on thin paperboard, paper sheet, leather, plastic film, aluminum foil, especially fit for coding on paper box of shoes and cloting. Adopt constant temperature control and the temperature is adjustable, suitabel for different material of color ribbon.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview: This machine is a kind of controlled by microcomputer programmable, photoelectric sensor, pneumatic operation in the integration of new and high technology, filling equipment. This machine is widely used in fluid materials, such as tomato sauce meat sauce sea food oil honey and so on . Filling dose accurately, no drop leak, can be applied to 50-600 ml, all kinds of bottle filling, switch in a few minutes filling specifications, filling in the same period is short, high production capacity, intuitive picture, the operation is simple, convenient, canned each set separately, grade of 0.01 seconds, greatly ensure the filling precision. After-sales service, 1-2 years free maintenance, life-long maintenance, the company has a professional after-sales service team, for the customer service 24 hours a day. Feature: (1) man-machine interface, directly set filling volume, filling volume and filling speed adjustment is simple, the touch screen operation and display, beautiful appearance; (2) PLC program control, frequency converter speed control linear filling After sale service: (1)Long life service (2)One year warranty (3)Offering free parts for one year (4)Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

This linear type pop can filling sealing machine is suitable for equal pressure filler and capper of drinks and oil, honey, butter, sauce and lots of products in beverage drink and food industry. It is in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. It is suitable for plastic can and tin can. The machine adopts PLC, frequency converter, human machine interface controlling system, having the advanced controlling technologies, such as frequency control; no can no filling and so on. The accurate production rate and quantity will be displayed on touchscreen via the kinds of sensors on the machine. Moreover, the production rate can be set on the touch screen. The main motor and other electrical equipments are all in protection state. Meanwhile all of the malfunctions can be found out easily, because they will be displayed on the touch screen. The main electric and pneumatic components of the machine are famous imported brands, and it also can be disposed according to client’s requirements. Features High production capacity and high automatic grade. Dropping caps and sealing automatically without human. Sealing without twist off which can protect the damage to cans No bottle no filling. Unique drip proof device in production process, ensure no irrigation constant filling function. PLC and touch screen, east and fast to operate. The automatic machine will alarm or stop working automatically if unconventional problems happen(such as counting mistake, miss bottles)

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Squared performance description: 1.The tank cover spreading device: when the body enters, only the corresponding rationing tank cover, no tanks, no cover; 2. PLC operation panel design is reasonable and simple, convenient adjustment and maintenance; 3.High production capacity, high degree of automation, suitable for sealing cans production line equipment; 4. 304 stainless steel appearance, sealing roller is made by chrome steel, high hardness, good wear resistance, no rust, excellent sealing performance. Squared characteristics description: 1.Unmanned operation, automatic under cover and seal, in accordance with the artificial prices rising trend, the equipment will become the mainstream models; 2.Tanks not rotating sealing process design, to better products and body protection, machining accuracy is high, the sealing quality is better than the domestic similar products. 3.The production efficiency of the machine is semi-automatic sealing machine 2 ~ 3 times, and because of using automatic under cover and sealing device, save manpower cost at the same time, improve the production efficiency; 4.Suitable for all kinds of tinplate cans, aluminum cans, paper cans, etc all kinds of round specifications sealing cans, simple to operate, is the ideal equipment of food, beverage, pharmaceutical and other industries.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:36

00:36

Overview: The main engine of cartoning packing machine adopt frequency control, PLC automatic control system. In the cartoning machine, all material has automatic detection device to detect and reject unqualified products. Adopt human-computer interface, operating is simple, operating speed and counting function are automatically displayed. Automatic folding instructions, one to four are adjustable, instructions are automatically sent into the box. Sync automatically print 2 to 4 row stamp batch. Achieve varieties of specifications adjustment in the same machine , adjustment is simple and convenient. 1.Equipment manufacture and technical features: 1.1 Equipment manufacture: 1.1.1 Outer surface: Our equipment use high quality stainless steel plate to cover the outer surface. The spare parts are chrome-plated and blackened, and having nitride treatment; the processing surface of exposed metals are smooth, no glitches, scratches or rust, all the parts do antirust treatment. 1.1.2 Materials: The materials of equipment which contact with packaging are stainless steel, non-metallic materials. They are non-toxic、non-polluting and have high chemical stability; chrome-plated protection uses non-toxic materials, key components use bearing steel in order to ensure the life of the machine. 1.1.3 Fasteners: The connected components of our equipment are firm and reliable, smooth flow of air control system and no leakage. Fasteners are firm without loosening. 1.4Technical features: 1.4.1Our equipments are beautiful, lightweight; small footprint, simple operation, easy maintenance and so on. High stability and applicability; comprehensive and cost-effective. 1.4.2 Our equipments meet the requirements of GMP. 1.4.3 Our equipments have integrated structure, advanced design, and they are stable and reliable. It is more convenient that we replace products with different specifications without replace parts within the specified range of packaging materials. 1.4.4 Our equipments use integration of mechanical and electrical gas, PLC control, man-machine interface & touch screen display. Fault display function is also included.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

The pineapple weighing filling capping machine is suitable for different kind of granule products . For example bean corn carbon peanut nut.The eleactric weighing machine High precision digital weighing transducer make accurate measuring The microcomputer control system, and adopt double vibrates to feed, import instrumentation, advanced technology, simple operation. Stainless steel sealing systems,Anticorrosion measures can quickly remove,Facilitate cleaning maintenance. Good compatibility with other packing equipment.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Products overview (1) filling system precision filling system precision mainly depends on the accuracy of metering pump, filling speed and stability of the system. (2) In view of the different diameter valves, we can be equipped with many sets of vibration plate material (3) Stainless steel quantitative filling, pneumatic piston pump cover, elevating screw cap.With filling, screw cap is smooth, simple operation, accurate measurement, etc. (4) The filling nozzles adopt anti-drip and anti-drawing filling device. The pump uses quick-fit removal Structure: easy cleaning and disinfection. Feature (1) This filling line can be used for perfume, insecticide, air freshener and so on. (2) Anti-blast motors are applied for tin unscrambler device and the conveyor.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview This Machine adopt auger to measure and fill powder and granular, with high filling speed and filling accuracy. The auger is driven by servo motor. It fits more to the fluidic or low-fluidity materials, like coffee powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on. The automatic small powder filling sealing machine ’s spiral driven by servo motor drive which is not easy to wear, it can fix position precisely, set the speed and work stably. It can add dust collect device in the outlet of material for filling without dust of the automatic small powder filling sealing machine An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Features It is applicable to different-shaped bottles and plastic bottles: plastic,glass bottle and mould bottle.The bottle-in and bottle-out has specialized structure .It doesn't drop bottles or nip bottles The surface of whole machine is made by stainless steel 304. Knockdown transparent hopper is easy cleaned. The hopper is specially made with a cover and a mix in it to prevent dust and make the powder even. The metering system is adjustable auger, which is driven by servo motor, with quick speed and high filling accuracy. PLC+ Human-computer touch screen control system: easy adjustment and easy operation. It also can save the parameters for later use. Online electronic scale can weight the powder gram automatically, ensure the filling accuracy. Bottle position correct device.To ensure the bottles and filling nozzles are in the correct position, we add a special bottles position device to make the whole filling process smooth and stable. No bottle no filling. Functions A high yield of cap-fastening Turntable fastness, replace simply and convenient. Come in and out bottle is easy, frequency conversion adjusting speed. Operate easily. It is easy maintenance. Concatenation work, automatism production, Saving time, improve efficiency. The whole machine is designed to meet GMP standard. Our advantages We provide our customers with all components for free within 1 year. We offer long life maintenance, technical support is available. We offer videos of installation and debugging. Our machine is easy for installation. We will take pictures of the disconnect parts of machines, you can install the machines according to pictures. We attach marks on the machines that need to connect, you can install the machines by yourselves. It is cost saving for you. The spare parts are optional according to customers needs. The handle of the machine can be freely and conveniently turned to adjust so that various types of bottles can be used.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview This piston pump filling machine is specially made for all viscous materials, such as peanut butter, honey, tomato paste, jam etc. The machine adopts piston pump and for filling. By adjusting the servo motor, it can fill all of the bottles in one filling machine, with quick speed and high precision. The machine adopts full-auto PLC and human-computer touch screen control system. For different volumes adjustment are no problem. All the touch production material is stainless steel 304. Characteristics 1 use good quality components and parts. 2 all design with rich experience 15 years. 3 humanization design concept to machine 4 Whole machine meet GMP standard. 5 All spare parts are meet client requires

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview This piston pump filling machine is specially made for all viscous materials, such as peanut butter, honey, tomato paste, jam etc. The machine adopts piston pump and for filling. By adjusting the servo motor, it can fill all of the bottles in one filling machine, with quick speed and high precision. The machine adopts full-auto PLC and human-computer touch screen control system. For different volumes adjustment are no problem. All the touch production material is stainless steel 304. Characteristics 1 use good quality components and parts. 2 all design with rich experience 15 years. 3 humanization design concept to machine 4 Whole machine meet GMP standard. 5 All spare parts are meet client requires

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview This metering pump filling machine is specially made for all viscous materials, such as water, gel, shampoo, oil etc. The machine adopts piston pump and for filling. By adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision. Feature 1. Adopts piston pump to fill, suitable for all kinds of liquid, high precision; The structure of pump adopts shortcut dismantling organ, convenient to wash, sterilize. 2. The piston ring of volumetric injection pump use different material of silicone, polyclonal or other kinds according to liquid characteristic, use ceramic pump in special industry. 3. PLC control system, frequency conversion adjusting speed, high degree automation. 4. No bottle, no filling, auto count the quantity. And have the anti-drop device. 5. Filling quantity of all pumps is adjusted in a lump, minim adjustable for each pump. Easy and quick operate. 6. Filling head is equipped with anti-dropping equipment, diving to the bottom to fill, rise slowly, to avoid bubble. 7. The whole honey bottle filling machine is suitable bottles in different size, easy adjusting, and can be finished in short time. 8. The whole machine meets GMP requirement. After sale service (1) Long life service (2) One year warranty (3) Offering free parts for one year . (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:39

01:39

Description: The machine is specially designed for small bottles such as e-liquid, eyedrop, syrup, essential oil, nail polish etc and widely used in the food, cosmetic, pharmaceutical, oil and other industries, It works automatically with high speed, adopts peristaltic pump to filling from 2-50ml with high precision, controlled by PLC, easy to operate and no bottle no filling and capping. Salient Features: The whole machine is safe, sanitary and eco-friendly, which adapts to various of working places. The filling nozzle is equipped with. peristaltic pump and run stable with high precision. The structure of peristaltic pump is easy to install and change for different flavor. Machine made of SS304, meet GMP standard and easy to take apart for cleaning. No bottle no filling, no plug no capping, production capacity automatically account. All controlled by the PLC and touch screen, easy to operate

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery