01:03

01:03

High Accuracy, Low Noise. C-type frame, high strength crank and connecting rod. YC1 series single-crank high-precison press has the features of high rigidity frame, high precision processing, lower noise. Equipped with color display device, all kinds of lights, counter, and production information, alarm information, maintenance information, improve operability. Advanced design, transmission center and machine center consistent; balance cylinder device makes the slider die run more smoothly; Screen display, crank position at a glance,locked type six-side long rectangle guides, bottom size of slide can be changed according to customers' requirement, This machine has different sizes and customers can choose different tonnages. Main Structure Features High rigidity frame High precision processing Lower noise Less synthetic clearance Locked type six-side long rectangle guides Less bending of die height, less deviation of kinetic energy Less punching deformation Convenient operation

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 00:58

00:58

Used for Automatic high efficiency production of aluminum fins. Servo feeder device, lifting stacker unit, scraps blowing unit can be provided as optional accessories. YKC series H-frame fins press line for the punching of air conditioner fins is specially intended for meeting the requirements of air conditioner fins. Equipped with optional die change system photoelectric protector. Buttons, indicators, AC contactors, air circuit breakers and other controlling devices are imported from internatioanal brand. Controled by PLC with international brand. The line is mainly consists of uncoiler, oil tank, fin press suction unit, stacker and relevant electrical control system. Imported The PLC, counter and contact point free cam controller are all imported,which meet the requirements of counting the fins cut collected as well as the function of progress change. Main Structure Features Composition: Uncoiler, oil tank, air feeder, fin press, suction unit and stacker, electric control system, air system, air system,hydraulic system. The slide of power press has hydro-lifting function which will be convenient for dies installation / commissioning. Power press speed & vacuum stacker is controlled by converter. Collector has protecting system for fault operation no material warning, no oil warning. Hydraulic overload protection for main machine. Equipped with hydraulic rapid-dies changing device, making dies change more quickly and convenient. Machine-human interface and PLC electrical control system ensuring the reliable operation of the automatic punching.

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 01:11

01:11

C-type frame, Convenient to operate. High strength body, Less deformation. The JH21 series C press is with dry clutch and hydraulic overloading with steel welded body and good rigidity. This C frame power press has six guide rail slides, which has a long and high precision to prolong its life span. The press is controlled by PLC electric centralized system, which includes emergency stop, inch, single, continuous operation specification with a drive output shaft, automatic feeding, and air cushion device. It is equipped with combined dry pneumatic friction clutch, so the engagement is smooth, the action is agile and the noise is low. And this crank press is of convenient maintenance. The vertical structure of crank-shaft is compact and beautiful. Main Structure Features High accuracy, reach JIS-Grade1 High rigidity, steel-welded frame High precision, 6-side long guide rail Dry type pneumatic cluth-brake unit Imported safety dual-solenoid valve for clutch High sensitive HOLP Automatic grease lubrication system (FDI) Frequency drive inveter PLC system Optional components: Output shaft, air cushion, slide knockout device, automatic feeder, etc

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 01:07

01:07

High rigidity frame, super long guides of slide, suitable for hot or warm forging Having offset load resisting capability, meet multi-station forging production High efficiency, High speed of slide, short contact time to the work piece, lengthen the mould life. MP series hot forging press With Combination type frame and hydraulic nut preloaded, effectively solving the problem of overload. With high inertia fiy-wheel, specially meeting parts foring and extrusion forming. With connection rod of two supporting points type and lengthened guide ways, which is good at offset-loading and easy to being equipped with robots or other automatic line, perfectly meeting multi-station progressive forging processs. The speed of slider is high, as a resuil it shortens the touching time to the parts and lengthens the die service life. “X” type guide gibs are adopts, which heat sensitivity for the guide clearance is low. Inclouding the functions such as lubrication monitor, tonnage monitor, buch temperature monitor, failure display, crank angle detection, system running display and so on. Main Structure Features With Combination type frame and hydraulic nut preloaded, effectively solving the problem of overload. With high inertia fly-wheel, specially meeting parts foring and extrusion forming. With connection rod of two supporting points type and lengthened guide ways, which is good at offset-loading and easy to being equipped with robots or other automatic line, perfectly meeting multi-station progressive forging processs. High efficiency, High speed of slide, short contact time to the work piece, lengthen the mould life. “X” type guide gibs are adopts, which heat sensitivity for the guide clearance is low. the shut height can be adjusted by motor automatically. The clutch-brake unit adopts pneumatic floating block structure, which is convenient and flexible for maintenance. Inclouding the functions such as lubrication monitor, tonnage monitor, buch temperature monitor, failure display, crank angle detection, system running display and so on. With touch screen (Human-machine interface), making it easily and conveniently to oparete or set parameters.

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 01:20

01:20

8-Step Variable Stroke 8-Side Long Guides Of Slide Automatic Oil Lubrication System JL21 series c-type frame stroke adjustable press used Steel-welded frame, high rigidity and less deformation, ensuring the capacity for bearing heavy load, high accuracy, reach JIS-Grade1, Emergent stop, inching, single and continuous movement. Eight-side long rectangle guides of the slide in high moving precision and high accuracy. The machine has dynamic balancing system, reducing the noise from vibration to improve working environment; PLC electrical control system allows various auto-equipment reprogrammed according to different requirements and perform various functions, to ensure high reliability and high adaptability. Hydraulic overload protection device achieving high sensitivity in effectively protecting against overload, to ensure convenient and reliable operation. Optional Components: Output shaft, Air cushion, Slide knockout device, Automatic feeder, etc Main Structure Features JL21 Series C-tpye Fins Press Line for the punching of air conditioner fins is specially intended for meeting the requirements for the production of air conditioner fins. The line mainly consists of uncoiler, oil tank, fin press, sucker, stacker and relevant electrical control system. Imported PLC , counter and contact point free cam controller are adopted to meet the requirements of counting the fins cut collected as well as the function of progress change. Equipped with hydraulic overload protection device and motorized die height adjustment device, except JL21-45B. Production lines of special specifications can be made subject to the user's requirements.

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 00:44

00:44

Technique ∙The dissolver is a fast, high-capacity disperser with a wide range of speeds and high level of efficiency ∙Push-button speed control ∙Speed indicator and automatic speed reduction ∙The product is accelerated radially by the dispersion disk, deflected to the top and bottom at the tank wall and directed back to the dispersion disk through formation of a vortex ∙Shear forces around the circumference of the toothed disk result in highly efficient dispersion, good wetting and deagglomeration ∙For high-viscosity products, a tank wall scraping device can aid the mixing and dispersing process ∙Hydraulic lifting/lowering device ∙Push-button stroke adjustment ∙Adjustable tank clamping mechanism ∙Stainless steel shaft and dispersion disk; additional product-specific mixing tools available depending on the application ∙Manufactured in accordance with CE guidelines Options ∙Application-specific tank cover designs ∙Vacuum design ∙Scraping device for tank wall ∙Temperature sensor ∙Timer ∙Design for ceiling installation with hinged head ∙Various explosion protection ratings ∙Special tank clamping mechanisms ∙PLC-controlled units Advantage ∙ Easy handling which reduces costs and time ∙ Customized solutions on request ∙ A wide range of variously equipped versions available for highest process safety ∙ Various, easily exchangeable mixing tools to increase the efficiency ∙ Temperature measurement by wand or agitator shaft which increases the reliability of the production process ∙ Optimal positioning of the mixing tool via hydraulic lifting/lowering device ∙ Dissolver only starts When the vessel is correctly positioned ∙ At the lowest possible speed ∙ Two-handed operation for lifting/lowering of the tank cover (optional design) ∙ Automatic switch-off, if the toothed disks are lifted above the level of the tank ∙ Protection against accidental contact with the rotating shaft ∙ Bellows serving as dust protection for the shaft

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 01:01

01:01

H-type whole steel-welded frame Suitable for single and multi-station stamping This frame presses spare has a steel welded body with the features of good rigidity, transmission gear gumming lubrication, low noise and stable transmission;The functions of Hydraulic overload protection device and automatic emergency stop guarante the safety of press machine and mould; The number of frame double crank presses is adjustable and applicable to different parts of the job requirements. Main Structure Features Alloyed steel double crank with reverse running, countersct the side force High off-set load capability in L-R direction High accuracy, reaches JIS-Grade1 Straight side structure and high rigidity, steel welded frame High precision, 8-side long guide rail Pneumatic clutch-brake unite Imported safety dual-solenoid valve for clutch High sensitive HOLP 500T (below 500) Automatic grease lubrication system, 500T (above) Automatic oil cycle lubrication system FDI (frequency drive inveter) PLC, encoder, cam controller Optional Components: Output shaft, air cushion, slide knockout device, automatic feeder, etc

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 01:25

01:25

High rigidity separated structure casting frame, with guide pillar / sleeve unit. Suitable for Automatic high speed stamping of motor lamination. J76 series straight side high-speed Two-point Press line is Separated-structure and high-rigidity cast iron frame, base and crossbeam are tightened by four tensile screw rods, with high rigidity and less deformation; Automatic temperature control system and using the thermal compensation technology to control the position of bottom dead center in high precision; Four point crankshaft supporting structure, enhancing the strength of crankshafts, less deformation, high rigidity and strong load deviation resistant capability. Gas chamber balance device, to balance the slide and the weight of upper die, ensuring the balance of the press in running; Imported pneumatic combination friction clutch-brake, with low noise, long service life, large clutch torque and small braking angle, to ensure reliable safety and flexible action The machine has dynamic balancing system, reducing the noise from vibration, extending the service life of the dies and improving working environment; Suitable for Automatic high speed stamping of motor lamination. Main Structure Features Separated structure and high rigidity cast-iron frame High strength eccentric alloyed steel crankshaft Imported bearings and four-point crank supporting structure(80-300T) Slide is guided by liner clearance-free ball bearing plunger bushes Low vibration and low noise Big torque, low inertia, pneumatic clutch-brake unit Hydraulic locking device for adjustment rods , ensuring the precision of bottom dead center Forced lubrication system, automatic temperature control system and using the thermal compensation technology to control the position of bottom dead center in high precision Programmable cam controller Touch screen

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 01:00

01:00

Main Structure Features The compacting press is a mechanical crank connecting rod type of hydraulic pressure assisted powder forming machine; It is a high strength steel plate welding structure with stable mechanical structure toughness, good rigidity and high precision as well as stable production quality; The compacting press has the ability of mold and mandrel step forming; Using the touch screen control, improving the operation. With a various fault description and easy trouble shooting, the compacting is easy to maintain; It has the modular floating frame, which can be disassembled independently; Combined pneumatic clutch and brake make the compacting power press machine has fast response speed with high safety.

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 00:44

00:44

Principle The milling basket, containing thegrinding bead is lowered into the millbase, the fast circulation of the millbase within the milling basket is generated by the dissolver disc and integrated pump wheel, a very narrow particle size distribution can be achieved very quickly. Characteristics: ● Suita for producing small batch product and middle test. Dispersing and grinding are finished in one machine and one container, no need extra pumps, piping, valves etc . ● Easy cleaning, no residues, convenient product replacement. ● Little grinding media required.Excellent grinding efficience and effect. ● Double-walled container for cooling and heating. ● Modular design of parts make it much more convenient to disassemble, maintain and overhaul, almost no need of professional maintainer. Materials Viscosity: ≤ 5000 cps Production Capacity: 50-3000L Application Industry: Suitable for dispersing, grinding materials in industries such as biology.pharmacy, cosmetic, food, paint, ink, color paste, dyestuff, fertilizer etc. Applicable Materials: Materials shall be with viscosity less than 5000cps, with comparatively high requirements of final grinding result or with many varieties such as emulsion paint, industrial paint, color paste, water-borne ink, fertilizer suspension, etc Product Advantages ● High grinding efficiency and excellent grinding result Driven by the strong kinetic energy, the zirconium pins drive the grinding medium inside the basket to carry out irregular movement. The mediums crush, friction with each other to grind the powder into smaller particle size within a short period. For general materials, it can be down to approx. 5um, some even can be down to submicron or even nano level. ● Convenient and safe operation Adopt hydraulic tank as liting actuator. Control the hydraulic up, stop, down through the oil pump, easy operation and stable.With different clamping types to fix the tanks properly to prevent from accident due to the tank displacement during operation.Little temperature increase, stable finished product. The tank working with the machine is with cooling jacket. Excellent cooling result can be achieved by inputting cooling water into the jacket when the machine is running . Normally thetemperature increase will be less than 10. Basket part with jacket can be customized.Customized options ● The machine can be Exproof type. ● Grinding chamber can be made of Zirconium. ● The machine can be vacuum type. ● The materials for the machine can be SS316L Working Principle The rotating motor drives the pins and dispersing disc to rotate at high speed, which makes the upper part of dispersing disc and inner grinding chamber become vacuum. The slurry is inhaled into grinding chamber. The grinding medium driven by the driving pin inside the chamber produces force in all directions,which put materialsunder the action of constant collision and friction to smaller the particle size andnarrow the particle size range. The vortex flow generated by high speed rotation dispersing disc absorbs materials out from the basket (grinding chamber), and the milled materials are absorbed again, excellent dispersing and grind result will be achieved. Lift the hydraulic piston by running the hydraulic pump to have the driving mechanism and grinding chamber lift up and down.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 01:20

01:20

C-type frame, stroke of slide is adjustable. Have automatic and circular oil lubrication system. JL21 series c-type frame stroke adjustable press used Steel-welded frame, high rigidity and less deformation, ensuring the capacity for bearing heavy load, high accuracy, reach JIS-Grade1, Emergent stop, inching, single and continuous movement. Eight-side long rectangle guides of the slide in high moving precision and high accuracy. The machine has dynamic balancing system, reducing the noise from vibration to improve working environment; PLC electrical control system allows various auto-equipment reprogrammed according to different requirements and perform various functions, to ensure high reliability and high adaptability. Hydraulic overload protection device achieving high sensitivity in effectively protecting against overload, to ensure convenient and reliable operation. Main Structure Features 8-step variable stroke length High accuracy, reach JIS-Grade1 High rigidity, steel-weided frame High precision, 8-side long guide rail Dry type pneumatic clutch-brake unit Imported safety dual-solenoid valve for clutch High sensitive HOLP Automatic oil cycle lubrication system PLC system Optional Components: Output shaft, Air Cushion, Slide knockout device, Automatic feeder, etc.

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 02:10

02:10

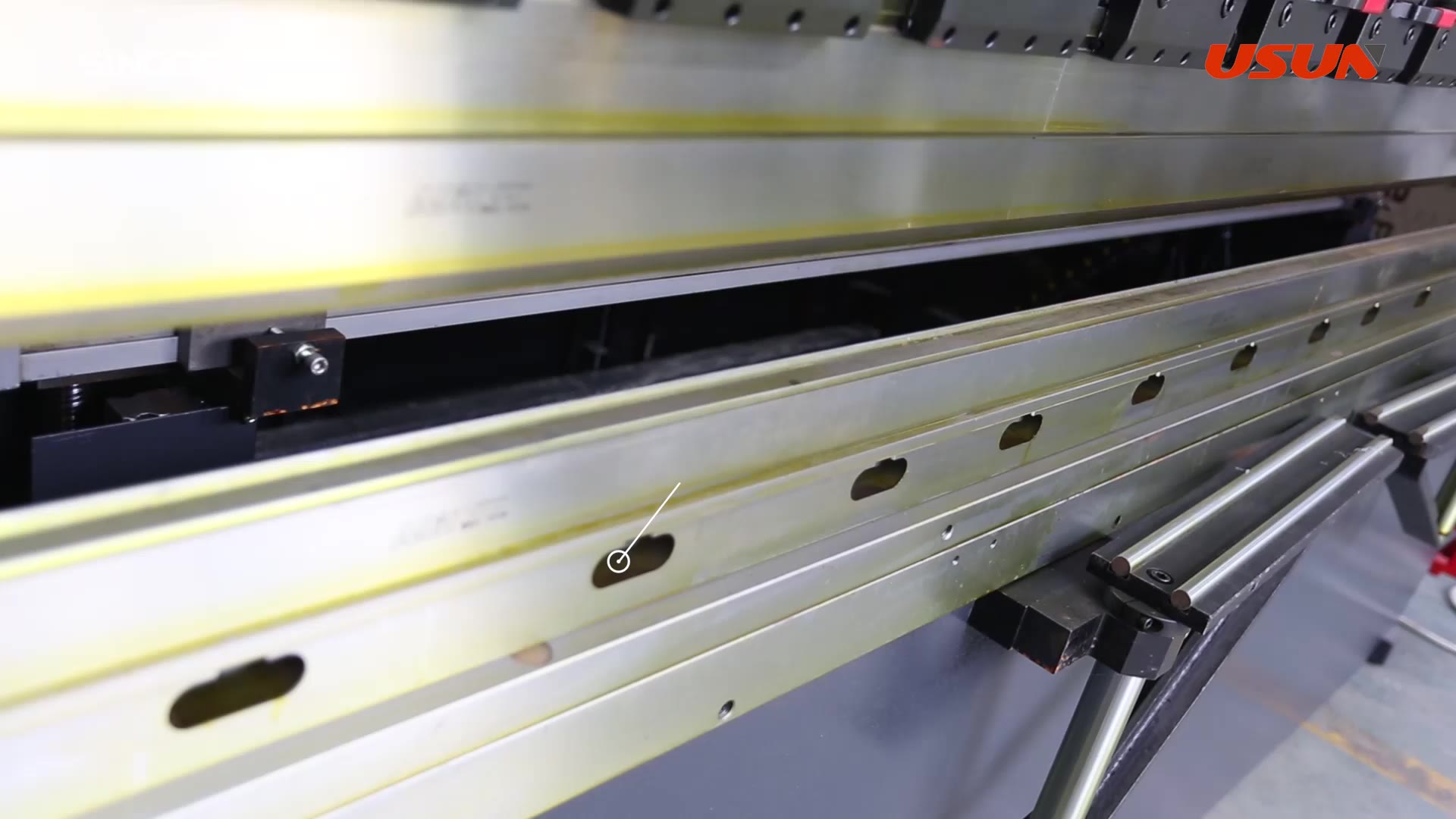

Standard Configuration : CNC sheetmetal pressbrake with streamlined desigh,hight speed ,hight precision,hight rigidity. Electro hydraulic servo system,full loop comtrolling the synchronizatio of the upperbeam. Equip with hydraulic crowning compensation on worktable and deformation compensation device on throat to make sure bending depth and precision. Backgauge is driven bu digital servo motor,moved by ball screw guided by linear guide. What should we know for choosing a press brake ? What’s your material of sheet ? What’s the minimum and maximum thickness of your sheet ? What’s the minimum and maximum width of your sheet ? What kind of product you make ? What’s the precision do you require for making products ? Machine Details: V-axis Table Compensation : V-axis is the CNC axis to control the adding convex amount of workbench, it can obtain accurate deflection compensation from the workbench. The adding convex workbench is made up of a group of beveled convex wedge, each wedge slope is designed by the deflection curve of finite element analysis of the slider and workbench vertical plate. CNC controller will calculate the required deflection amount according to the load when the work piece is working (The load will lead to the deflection and deformation), automatically control the relative motion of the convex wedge, and finally get an ideal work piece.

ADH Machine Tool is a professional manufacturer of bending machine, shearing machine, Our company is in the production of large bending machine, shearing machine ranked in the top five companies in the Domestic.the factory located in China. The registered capital is 33.8 million yuan. Annual production capacity of equipment is more than 5000 sets, assets more than 300 million. Our company is in strict accordance with the ISO9001:2008 international quality system to manage.product passed CE certification,Germany TUV certification and CQC China quality certification. We have 3 independent invention patents, 28 new patents. Donghai Machine Tool Co.,Ltd not only can meet special requirement of our customer, but also make personalized sheet metal processing equipment. So far,our products has sold to Europe (Russia,Poland, Germany,Ukraine) South America(Colombia, Argentina, Chile, Brazil, Peru)Middle East and Southeast Asia(India, Saudi Arabia, Egypt, Iran, Israel, Malaysia and Vietnam and so on).

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery