Brief Introduction

YX Chocolate Chip Production Line, confrms to the food GMP standard, is an advanced equipment for producing water drop and button shapes chocolate. High-degree automation ensures of stale production and saves time, labor force and occupation to serve purpose of reducing the cost

Chocolate chip making process

Sugar grinding--Cocoa butter melting-- Conche --Storage tank --Depositing and cooling --Packing

The functions of each machine.

1) Sugar grinding machine: Grinding sugar to sugar powder

2) Cocoa butter melting tank: jacket layers inside warm water, electric or steam heating, melting cocoa butter for 30-60 minutes, temperature is around 55-60 degrees

3) Conche:adding grinded sugar powder, coco powder, lecithin and cocoa syrup and so on into the conche for grinding 14 hours

4) Storage tank: Stirring the conched syrup for 3-4 hours until the bubbles disappear

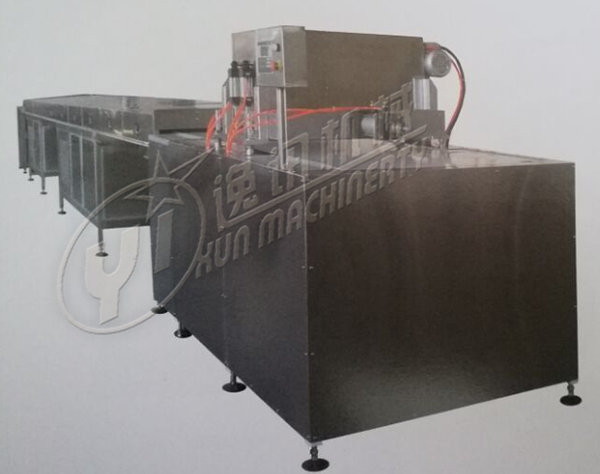

5)Deposting and Cooling: depositing the chocolate syrup to the PU belt and cooling. accuarte dosing, easy operate and large output

6) Packing machine: various packing machine available.

Technical Parameters

| Model | YX400 | YX600 | YX-800 | YX1000 | YX1200 |

| Machine length(m) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

| Depositing Speed:(times/min) | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Belt Width(mm) | 400 | 600 | 800 | 1000 | 1200 |

| Each Chip Weight | 0.1-3 | 0.1-3 | 0.1-3 | 0.1-3 | 0.1-3 |

| Cooling Tunnel Temprature | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 |

Tips on the chocolate production line:

1) The whole line equipped the international motor: ABB motor, Danfoss invertor, Mitsubishi PLC control, Servo motor, SS materials

2) Heating by steam or electric

3) water drop and button shapes chocolate can be made

Pictures and final chocolate samples: