Brief Introduction

YX Hard Candy Production Line, confrms to the food GMP standard, is an advanced equipment for producing various shapes and colors of hard candy. ideal equipment for continuous production of high quality single and double color hard candy. High-degree automation ensures of stale production and saves time, labor force and occupation to serve purpose of reducing the cost

Hard candy making process

Sugar melting--Storage tank-- Micro-film cooker --Depositing and cooling--Packing

The functions of each machine.

1) Sugar melting tank: heating sugar, glocose, water to 110 degrees.

2) Storage tank: storage the sugar syrup and and filting pure syrup.

3) Micro-film cooker: cooker the syrup again to 145 degrees for better taste, moisture is lower then 2%, suits for international standard.

4)Deposting and Cooling: depositing the sugar syrup into different candy mouds

5) Packing machine: various packing machine available.

Technical Parameters

| Model | YX-150 | YX-300 | YX-450 | YX-600 |

| Standard Output | 150kg/h | 300kg/h | 450kg/h | 600kg/h |

| Max.Candy Weight | over 4 gram | |||

| Depositing Speed | 40-45/min | 40-45/min | 40-45/min | 40-45/min |

| Steam Requirement |

0.2m³/min, 0.4-0.6Mpa |

0.2m³/min, 0.4-0.6Mpa |

0.2m³/min, 0.4-0.6Mpa |

0.2m³/min ,0.4-0.6Mpa |

| Working Requirement | Room Temperature: 20~25℃ Humidity: 55% | |||

| Total Power | 18kw/380V | 27kw/380V | 34kw/380V | 38kw/380V |

| Total Length | 15m | 17m | 17m | 20m |

| Total Weight | 3500kg | 4000kg | 4500kg | 5000kg |

Tips on the hard candy production line:

1) The whole line equipped the international motor: ABB motor, Danfoss invertor, Mitsubishi PLC control, servo motor, SS materials

2) Heating by steam or electric

3) Essence and pigment pump installed with the machine.

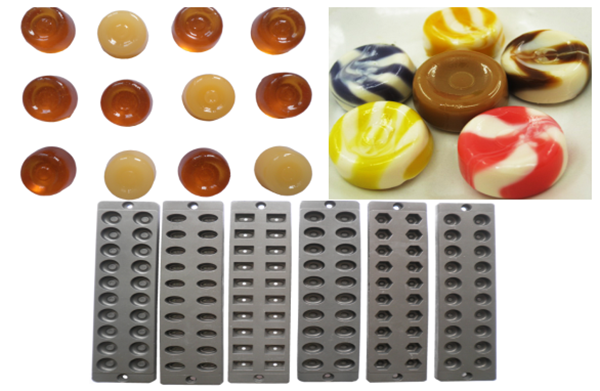

4) Various shapes hard candy can be produced by changing moulds

5) Candy size and weight effects the final output

6) One/ two colors/center fillied hard candy can be made

7) 260 pieces candy moulds for the 150 type, 520 pieces for the 300 type

Pictures and final hard candy samples: