00:20

00:20

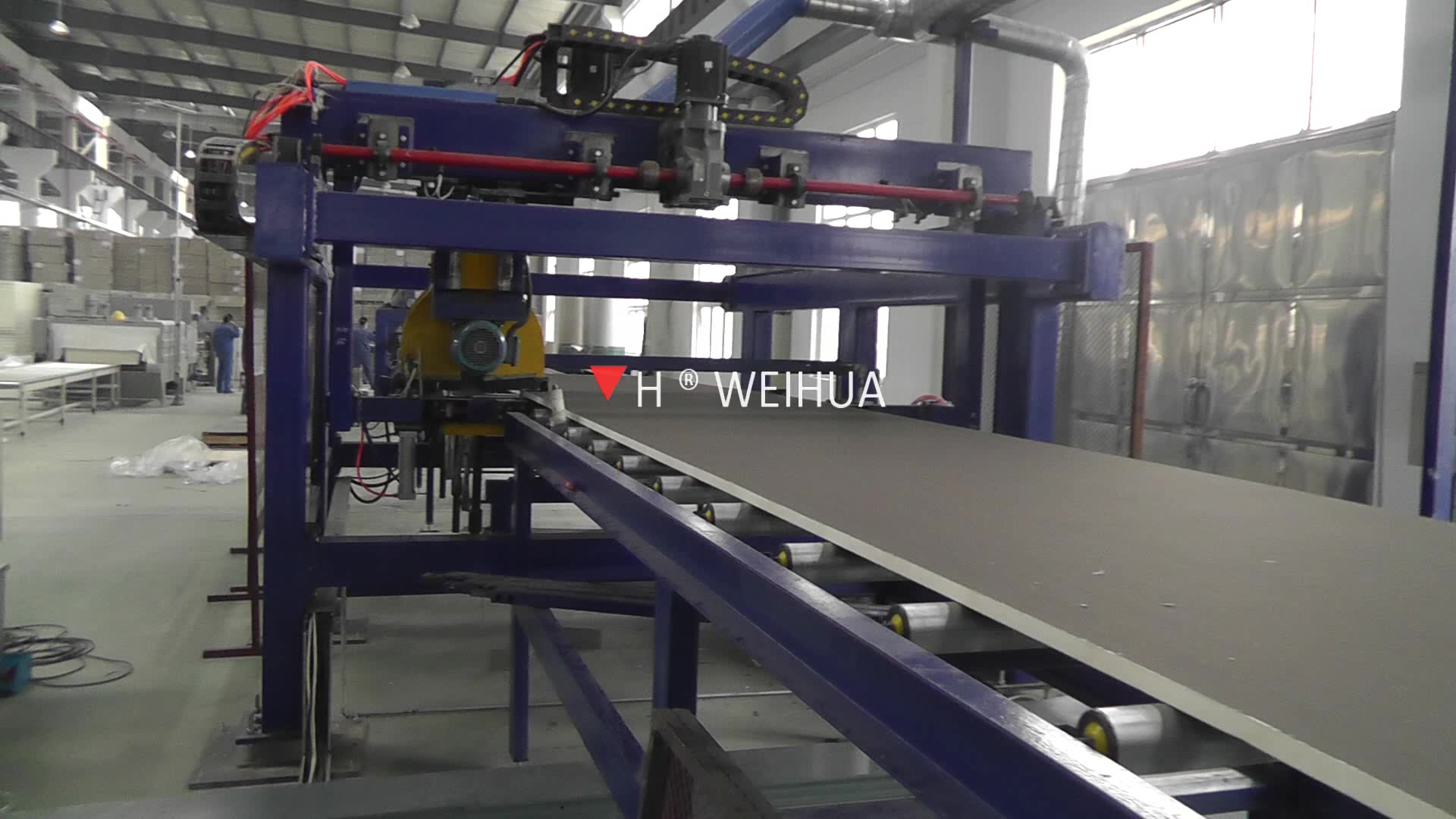

This device is used for changing the direction of rock wool to keep it parallel to the main line, thus prepare for the next step. The rock wool is on the transverse slide of turning machine which is driven by synchronous air cylinder. The machine is used for moving the rock wool from lengthways roller to transverse roller, that is to say, the lengthways motion change into transverse motion.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:21

00:21

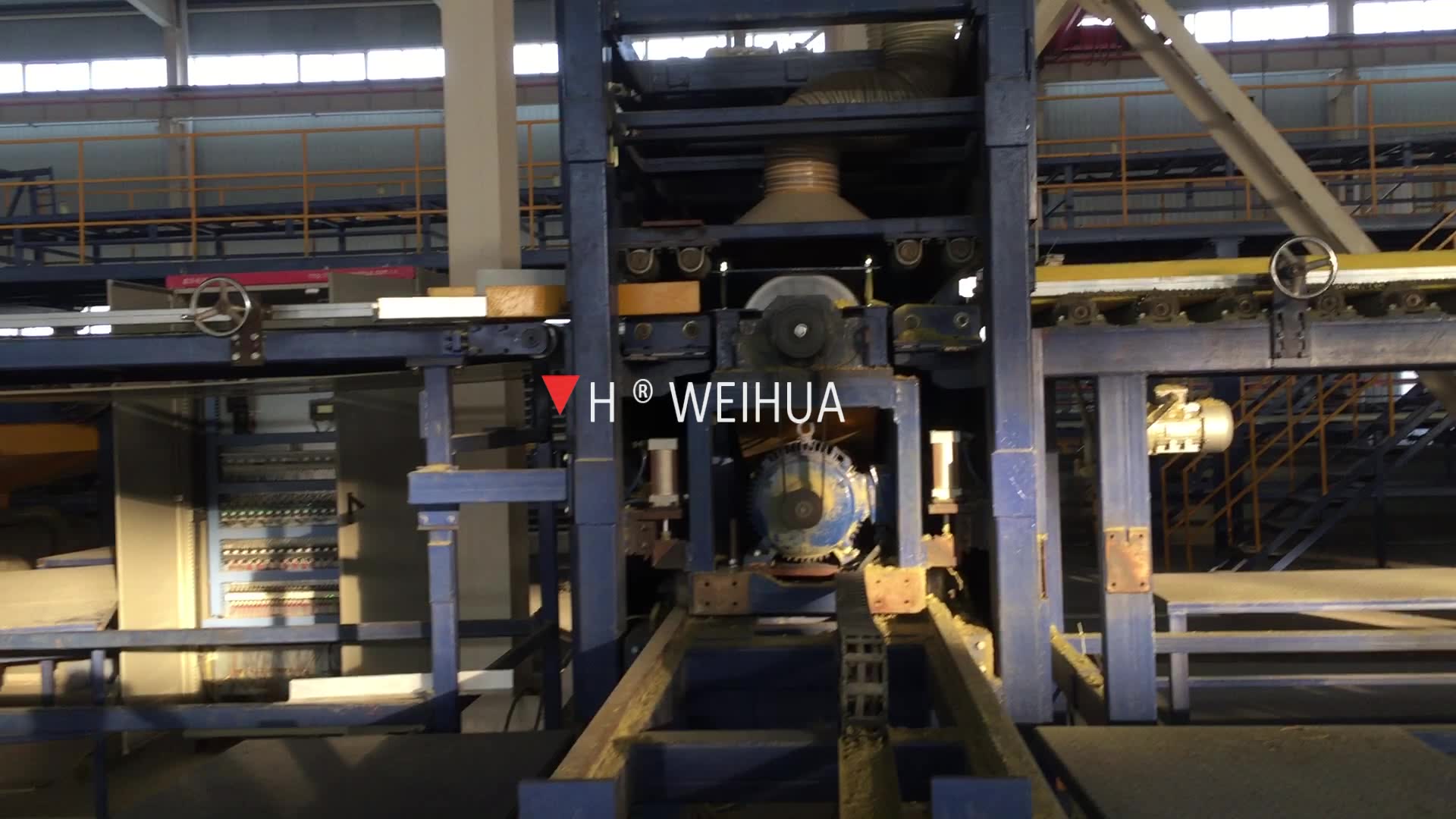

Disk saw contains encoder servo tracking device, disk saw, working table, dust-extraction unit, adjustable roller, fast roller and so on.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 01:31

01:31

Solid shaft diameter 85 mm or more according to design Wall thickness 20mm Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 00:56

00:56

In July,2012, Weihua provided the whole set of flexible surface sandwich panel line to Nanjing Hongbaoli Co., Ltd., which has multiterm of top-level patent technology, such as side seal of sandwich panel, up & down surface material deviation correction centering and detecting, surface material connection and energy-saving of double-belt conveyor. The width of sandwich panel output from double belt conveyor is 1203mm (without side trimming), base on two shift daily output, every year can save the PU material of about 1.5 million, especially double belt conveyor whose heat preservation system can save 30% energy consumption for customer. The correction device of soft substrate decoiler is one of the core part of the whole production line. It can decoil smoothly for soft substrates such as kraft paper、asphalt fabric、cement mortar paper & fabric、aluminium foil and so on and then supply to double-belt conveyor to solidify.The keypoint of the correction device is to solve the problem of non-centring and correct the deflection.The precision can be controled within 2mm. This device lays the foundation for saving more material when side seal for double belt conveyor.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:20

00:20

The function of rock wool slitting machine is to cut the rock wool block into corresponding width to meet the dimension of the final composite panel. In addition, it lays the foundation for the turning over and interface arrangement. Through conveying roller and positional guiding, the rock wool enters into the slitting machine. The slitting blade is designed with high-precision. The cutter is manufactured according to different thickness, that is to say, each thickness is matched with one set of cutter. When change different standard, hydraulic cylinder will push the cutter out and guide rail conveys the cutter. The position of cutter is locked by locating pin to materialize shock-proof and high precision cutting. It lays the foundation for the high-quality panels as the width of rock wool is consistent.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 02:42

02:42

Special rollers design, more precise and solid Solid Shaft diameter: 75 mm according to profile Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 00:17

00:17

WH-PU-6-40 six-components continuous high pressure foaming machine adopts online mixing model , low pressure pre-mixing and high pressure collision . With the feature of low pressure high speed cutting mixing and high pressure collision , it is the best pentane foaming machine .These six components are :1) Poly 2) ISO 3) Fire retardant : TCPP 4) Catalyst :KatA 5) Catalyst katB 6) pentane foaming agent . Every component is individually metered. Driven by magnetic coupling and variable frequency motor , the high precision pump realize close-loop flow with accurate volume and quality flowmeter (catalyst and foaming agent). It can change output flow and mixing proportion automatically . This foaming machine work on line . Pentane is harder to dissolve in Poly than 141B, so we adopt pre-mixing of low pressure high speed cutting .Materials, including Poly .fire retardant. catalyst .foaming agent , are transported to separate moving mixer by separate meterting pump . In order to improve foaming effect and make the mixed polyether fully integrated to nuclear air, we adopt one set of high-precision gas metering device, which can make mix the air and integrated Poly fully after emulsifying and high speed shearing. The output mixed polyether and ISO will go through high precision and pressure metering unit. When they reach to150 bar, they will spray together and finish complete mixing. The total set of unit adopts human-computer interface, which can display working process, various technological parameter including component flow、mixing ratio、mixed model. All the data can be sated and amended on the operating panel. There are some signal communication interfaces between electrical controlling system and production line. Once the speed of double belt changes, various material flow of foaming machine also changes as same ratio simultaneously to keep the final panel quality and realize the double belt work automatically.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 01:56

01:56

These extrusion line consist of conical twin screw extruder, mould and related downstream equipment. Application: for furniture and construction material, advertisement plate, inside upholstering plate for carriage of ship/car/train. Type PVB-1400 PVCB-1700 Product width 1220mm 1600mm Product thickness 3-20mm 5-25mm Extruder type SJZ80/156 SJZ92/188 Max. extrusion capacity 400kg/h 600kg/h Main motor power 75kw 132kw

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 02:05

02:05

Imitation marble decorative sheet extrusion line adopts a special curing technology, to provide a mirror effect on the product surface, with a strong artistic appeal, can create a magical change, bright colors, the magnificent visual effects. Product saturation film surface, similar to ceramic stone transparent glass layer, it can achieve such as stone-like three-dimensional affect, with high hardness, impact resistance, acid-resistance, weathering-resistance, low coefficient of expansion, non-absorbent, good flatness and other advantages, and the exclusion of natural stone harmful substances and radiation elements, is an ideal new generation of green building materials. Specification: Extruder type 1220*2440MM Product thickness 1-4.5MM Max. extrusion capacity 350-450kg/h Main motor power 55KW

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:15

00:15

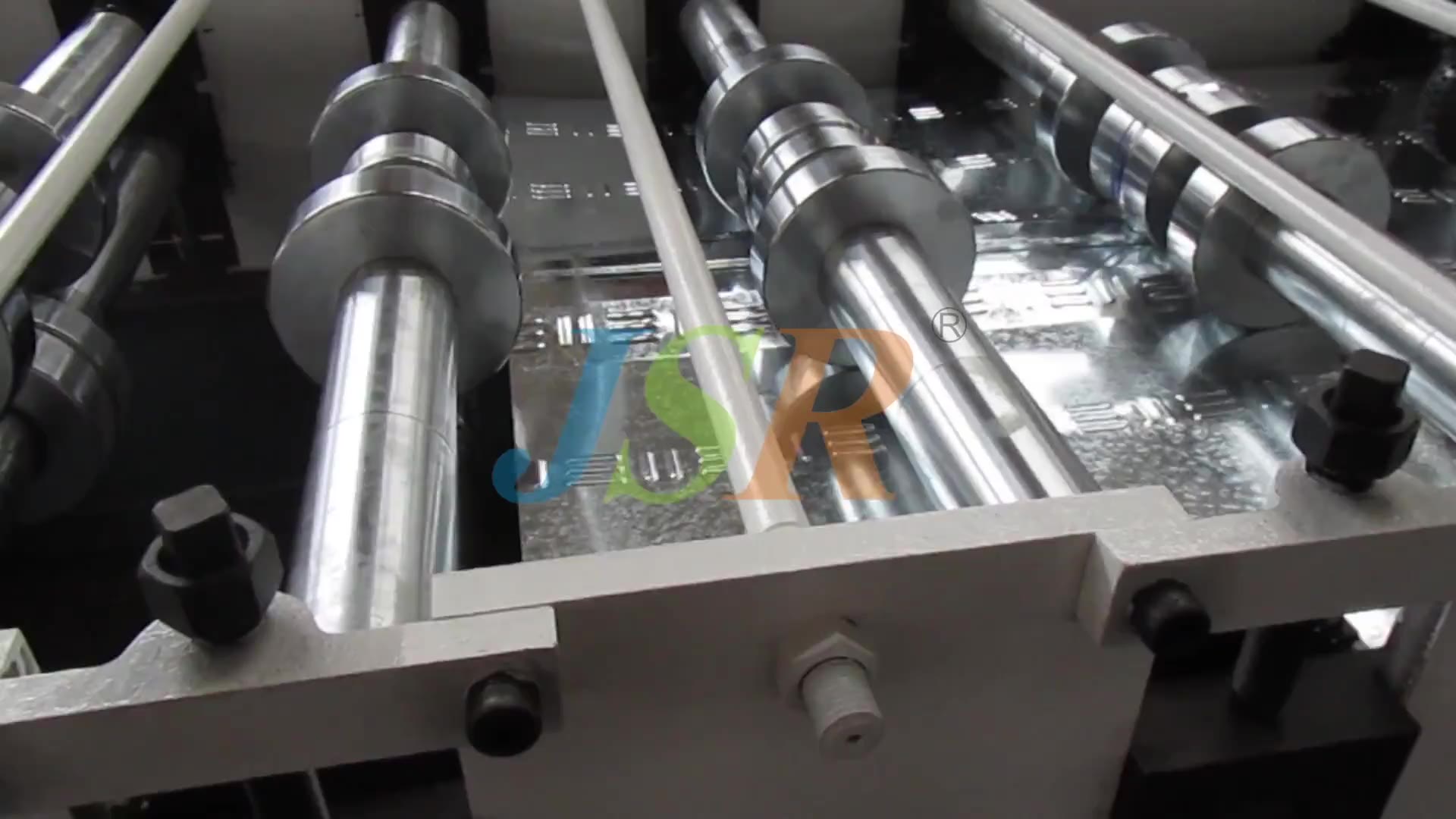

1. The whole forging parts with high rigidity and intensity. 2. Integrally processed, reduce the accumulating tolerance, high accuracy. 3. The bigger the diameter of roller is, the better the intensity is. 4. Surface carburizing, the surface hardness is high. 5. Wear-resisting, using life is long.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 01:45

01:45

PVC Plastic Roof Tile Making Machine is consist of conical extruder, co-extruder, die head, and auxiliary units to produce single layer PVC or PVC/PMMA, PVC/ASA composite roof tile. The whole line has reasonable design, high efficiency production, easy operation. Product width 880-1040mm Product thickness 2-4mm Extruder type 80/156&45/30 Output capacity 390 Length of machine 26m

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:50

00:50

Feeding and filming unit has the function of conveying steel panel, the plastic film can protect the surface of steel panel to avoid scratch. Filming device adopts air expanding roller to fix the film coil (inner diameter is ∮75mm); press roller and support roller are drum type with power, which is convenient and reliable. It has the adjusting at both left and right side for the film coil, which can guarantee the position accord with steel panel, so that the filming can be flat and without bubble & gauffer. The shaft for fixing film coiling block can rotate; left and right operation is convenient.The expanding roller pull out the production line via guide railway,clamping and replacement,and ensure the operation safe when continuous producing.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery