00:00

00:00

YF series PVC profile production line is mainly for producing PVC window profile, according to different profile section and mould to choose different conical or parallel twin-screw extruder and provide relative vacccum sizing tank, haul-off, cutter, stacker and auxiliary equipment. Capacity of main frame can be optionally chosen from 60-700 kgs/hour. The haul-off unit has applied unique lift technique of our co. Its work is stable, its reliability is good, its pulling force is large. Vacuum setting has applied special enlarged vortex cooling system which is good for cooling and calibrating so as to meet demand of high speed extruding. Movement speed and drawing speed of cutting machine keep synchronous. All movements are controlled by imported PLC, the design is reasonable, the operation is stable, it can conduct automatic cutting with fixed length. Powder & dust suction device can be provided. With different molds, the tilter platform can choose such specifications as 4-meter, 6-meter, 8-meter, 11-meter, etc. With twin parallel screws extruder, it is particularly suitable for high speed extruding of profiled material. Model SJZ45/90 SJZ50/105 SJZ55/110 SJZ65/132 SJZ80/156 Motor power 15 18.5 22 30-37 55 Screw diameter 45/90 50/105 55/110 65/132 80/156 Screw rotation speed 34.7 34.7 34.7 34.7 34.7 Output capacity(PVC) 60-80 80-100 120 150-250 250-400 Model YF108 YF180 YF240 YF300 YF400 Max. profile width 108 180 240 300 400 Haul off width 100 100 150 150 150 Haul off force 2 2 2 2 3 Haul off speed 0-6 0-5 0-5 0-5 0-5 Total power (without extruder) 9.9 18.7 27.5 31 35

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:22

00:22

Mineral wool interlace arrange: make the wool strips interlace arrange and disperse the strips’ joints, avoid the gathering of joints and become faultage. After turning , the rock wool enter into the conveying roller, interlace arrangement before enter the conveying belt, and tightened by the side belts to achieve the best bonding effect with steel plates. This structure can adopt irregular rockwool, those broken rockwool can also used durling production.

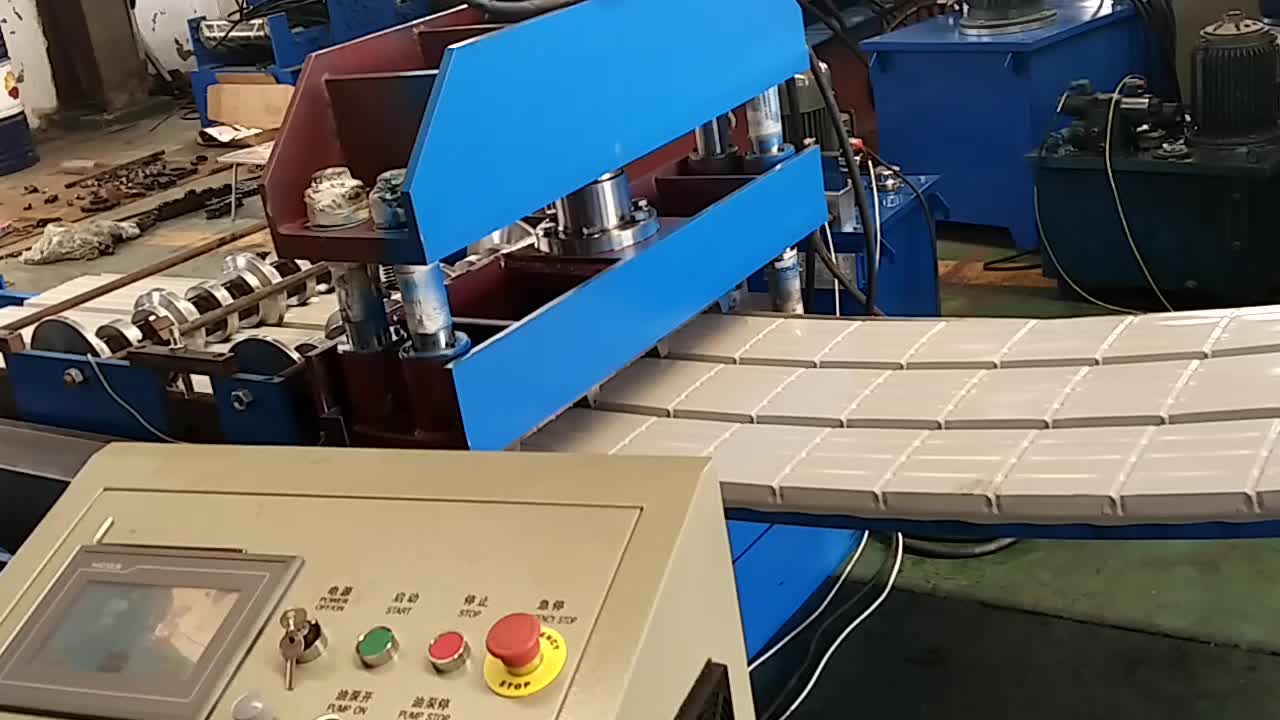

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:00

00:00

YF series PVC profile production line is mainly for producing PVC window profile, according to different profile section and mould to choose different conical or parallel twin-screw extruder and provide relative vacccum sizing tank, haul-off, cutter, stacker and auxiliary equipment. Capacity of main frame can be optionally chosen from 60-700 kgs/hour. The haul-off unit has applied unique lift technique of our co. Its work is stable, its to meet demand of high speed extruding. Movement speed and drawing speed of cutting machine keep synchronous. All movements are controlled by imported PLC, the design is reasonable, the operation is stable, it can conduct automatic cutting with fixed length. Powder & dust suction device can be provided. With different molds, the tilter platform can choose such specifications as 4-meter, 6-meter, 8-meter, 11-meter, etc. With twin parallel screws extruder, it is particularly suitable for high speed extruding of profiled material.reliability is good, its pulling force is large. Vacuum setting has applied special enlarged vortex cooling system which is good for cooling and calibrating so as Model SJZ45/90 SJZ50/105 SJZ55/110 SJZ65/132 SJZ80/156 Motor power 15 18.5 22 30-37 55 Screw diameter 45/90 50/105 55/110 65/132 80/156 Screw rotation speed 34.7 34.7 34.7 34.7 34.7 Output capacity(PVC) 60-80 80-100 120 150-250 250-400 Model YF108 YF180 YF240 YF300 YF400 Max. profile width 108 180 240 300 400 Haul off width 100 100 150 150 150 Haul off force 2 2 2 2 3 Haul off speed 0-6 0-5 0-5 0-5 0-5 Total power (without extruder) 9.9 18.7 27.5 31 35

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:00

00:00

Change size within 10 minutes Change between C and Z within 30 minutes

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 00:00

00:00

The production line includes screw feeder, plastic extruder, mould, vacuum forming table, haul off unit, cutting machine, stacker. Auxiliary equipments: mixer, crusher, pulverizer, lamination machine, hot stamping machine, printer and so on. Features: High filing material, even plasticizing, lower percentage of additive material are needed, stable production, and easy operation. Specifications Model SJZ48 SJZ55 Motor power 18.5 22 Screw diameter 48/112/115/118 55/110/120/125 Screw rotation speed 34.7 34.7 Output capacity(PVC) 80-100 100-150

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:00

00:00

This profile production line is according to different profile section and mould to choose different conical or parallel twin-screw extruder and provide relative vacccum sizing tank, haul-off, cutter, stacker and auxiliary equipment. Capacity of main frame can be optionally chosen from 60-700 kgs/hour. The haul-off unit has applied unique lift technique of our co. Its work is stable, its reliability is good, its pulling force is large. Vacuum setting has applied special enlarged vortex cooling system which is good for cooling and calibrating so as to meet demand of high speed extruding. Movement speed and drawing speed of cutting machine keep synchronous. All movements are controlled by imported PLC, the design is reasonable, the operation is stable, it can conduct automatic cutting with fixed length. Powder & dust suction device can be provided. With different molds, the tilter platform can choose such specifications as 4-meter, 6-meter, 8-meter, 11-meter, etc. With twin parallel screws extruder, it is particularly suitable for high speed extruding of profiled material. Model SJZ45/90 SJZ50/105 SJZ55/110 SJZ65/132 SJZ80/156 Motor power 15 18.5 22 30-37 55 Screw diameter 45/90 50/105 55/110 65/132 80/156 Screw rotation speed 34.7 34.7 34.7 34.7 34.7 Output capacity(PVC) 60-80 80-100 120 150-250 250-400 Model YF108 YF180 YF240 YF300 YF400 Max. profile width 108 180 240 300 400 Haul off width 100 100 150 150 150 Haul off force 2 2 2 2 3 Haul off speed 0-6 0-5 0-5 0-5 0-5 Total power (without extruder) 9.9 18.7 27.5 31 35

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:14

00:14

Main technical parameters: Forming speed: 8-12m/min; Forming thickness: 1.0-3.2mm; Forming stations: 18 steps; Main motor power: 37kw; Controlling system: PLC frequency conversion controlling, Japanese Omron Encoder; Application The scaffolding plank roll forming machine line is used to produce the scaffolding planks, which are used for construction materials. Video

Wuxi Yuanding Machinery Co., Ltd. is specialized in building materials of light steel structure. Since the factory founded 20 years before, it’s always design and produce various type profile of roll forming machine.

Contact Supplier 00:48

00:48

Main technical parameters: Forming thickness: 0.3-1.5mm; Main motor power: 4kw; Application The arc bending machine is used to bend the finished forming panels.

Wuxi Yuanding Machinery Co., Ltd. is specialized in building materials of light steel structure. Since the factory founded 20 years before, it’s always design and produce various type profile of roll forming machine.

Contact Supplier 00:00

00:00

Special rollers design, more precise and solid Shaft diameter: 55mm or more, according to profile Wall plate 18mm thick Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 00:00

00:00

Special rollers design, more precise and solid Shaft diameter: 75mm, according to profile Mitsubishi PLC and converter Tool box and technical support Guide pillar design

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 00:00

00:00

Solid shaft diameter 85 mm or more according to design Guide pillar, looks beautiful and easy to mantain Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 00:00

00:00

Special rollers design, more precise and solid Shaft diameter: 55mm or more, according to profile Wall plate 18mm thick Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery